Extrusion Velvet Sofa

Design and photography by AANDERSSON

Published in Spring 2019

This sofa employs one of the simplest production processes of any structured and refined sofa in production today. The design is a result of countless compromises, experiments, and simplifications to distill the assembly to 24 steps that can be done within the course of about 6 hours by anyone that has the right tools and enthusiasm. The 26 pieces of lightweight aluminum framing can be completely taken apart and re-assembled in 30 minutes for easy moving. Parts for this difficult to assemble design cost on average 700 USD.

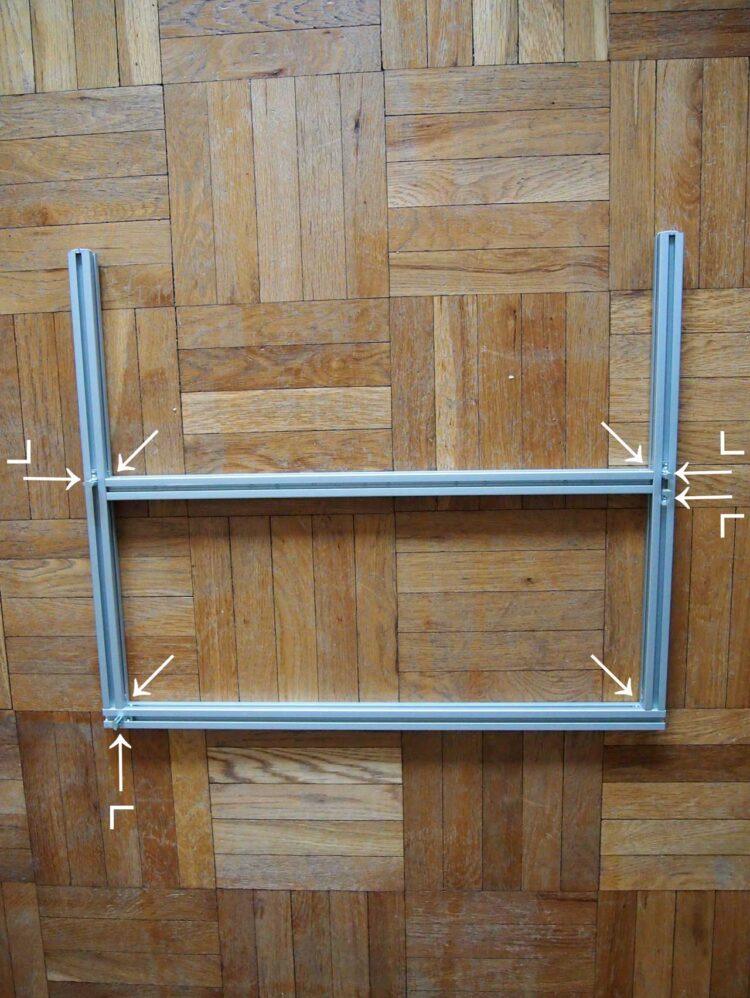

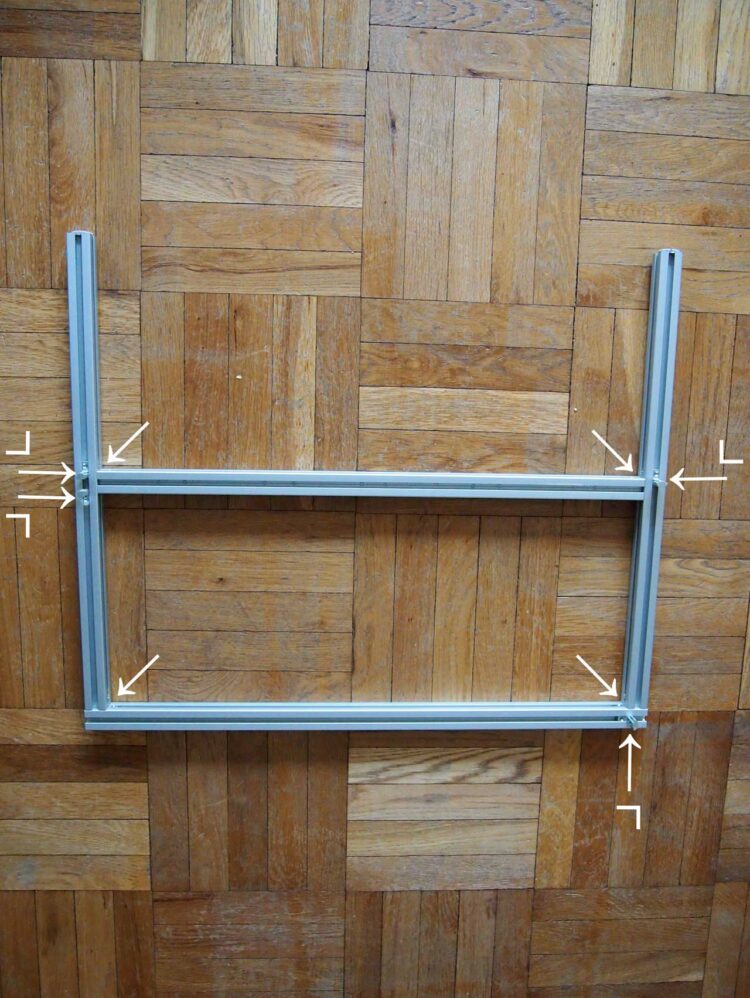

Assembly

Index

Parts

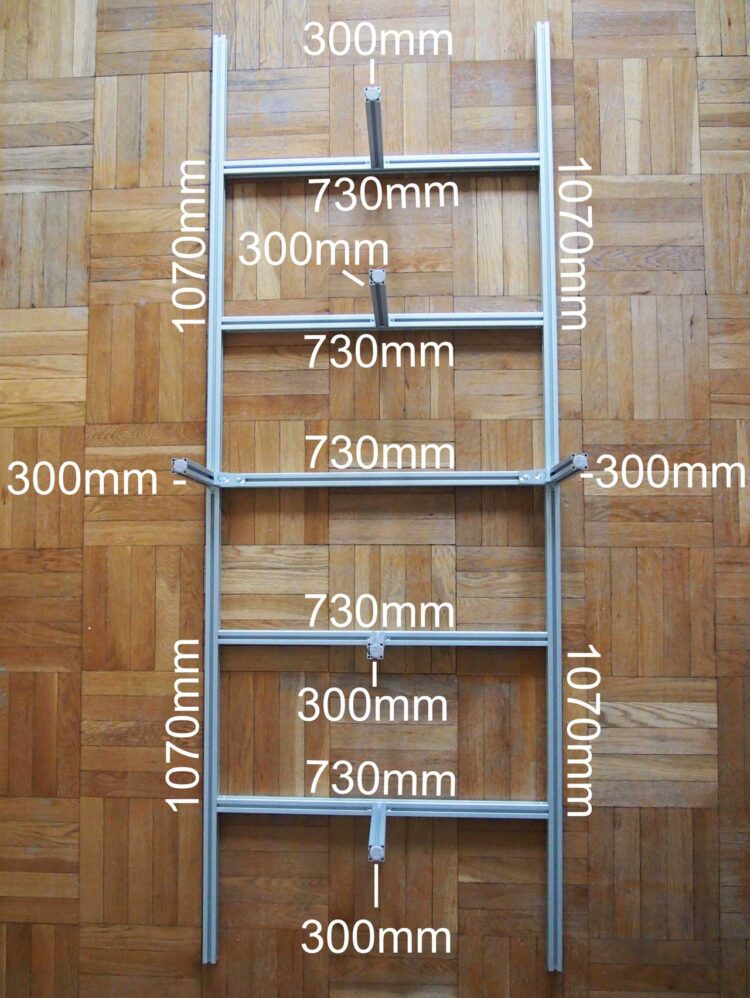

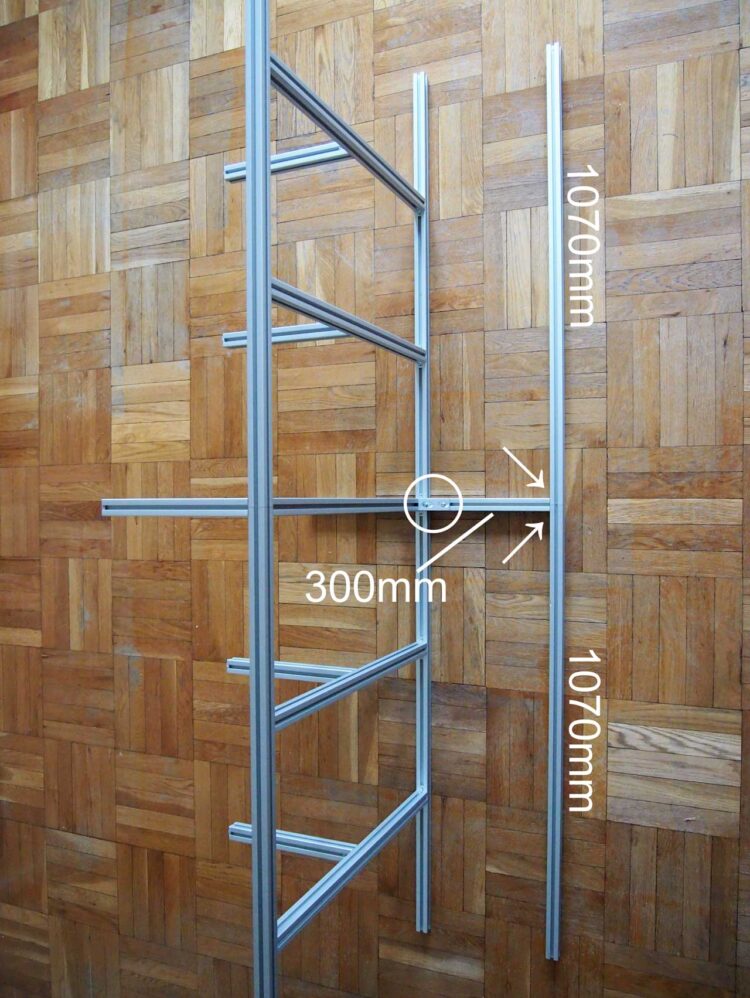

Anodized T-slotted Aluminum Frame, 30mm x 30mm

Quantity required: 6 x 1070mm length, 7 x 730mm length, 7 x 300mm length, 2 x 790mm length, 4 x 630mm length

HD36 High Quality Cushion Foam, 5in (13cm) thickness

Quantity required: Two of each: 25in x 37in (63cm x 94cm), 18in x 30in (46cm x 76cm), 18in x 37in (46cm x 94cm)

Polyester Fiberfill Batting, 60in x 15ft (1.5m x 4.5m), 1in (2.5cm) Thick

Quantity required: 1

Tools

Hex Keys, M6 and M5

Hand Saw

Sewing Machine or Sewing Needles

Gutermann Extra Strong Thread

Clear 5 minute Epoxy Glue

Alternative Parts

Velvet Upholstery Fabric, 10yd (9m), More Colors

Replaces: Slate Velvet Upholstery Fabric, 10yd (9m)

Help Each Other