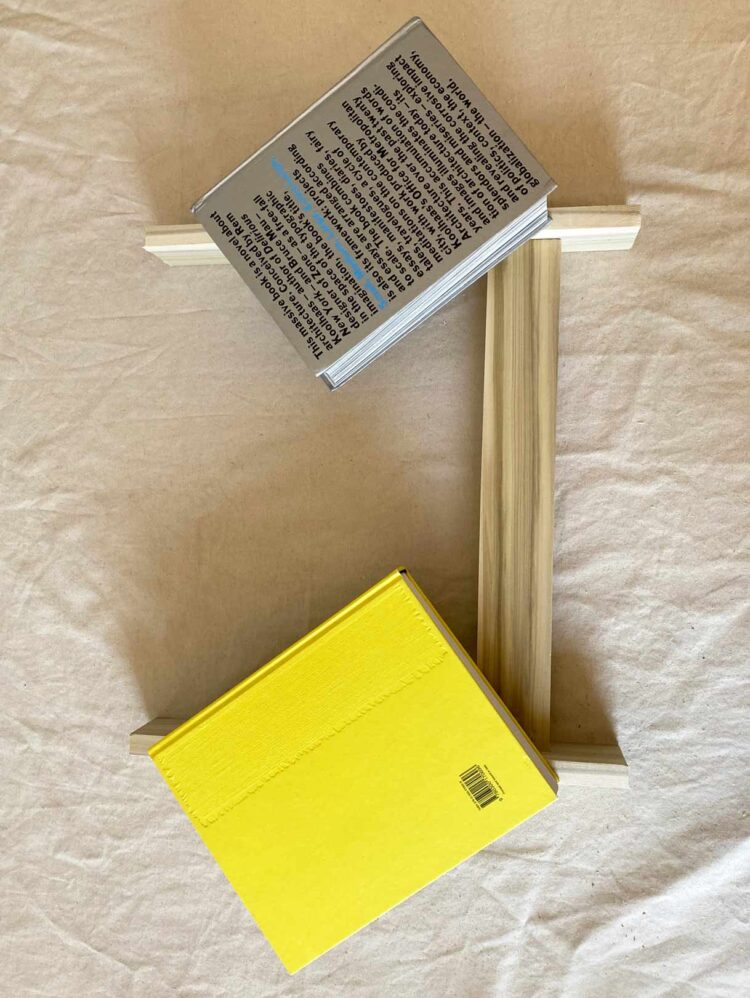

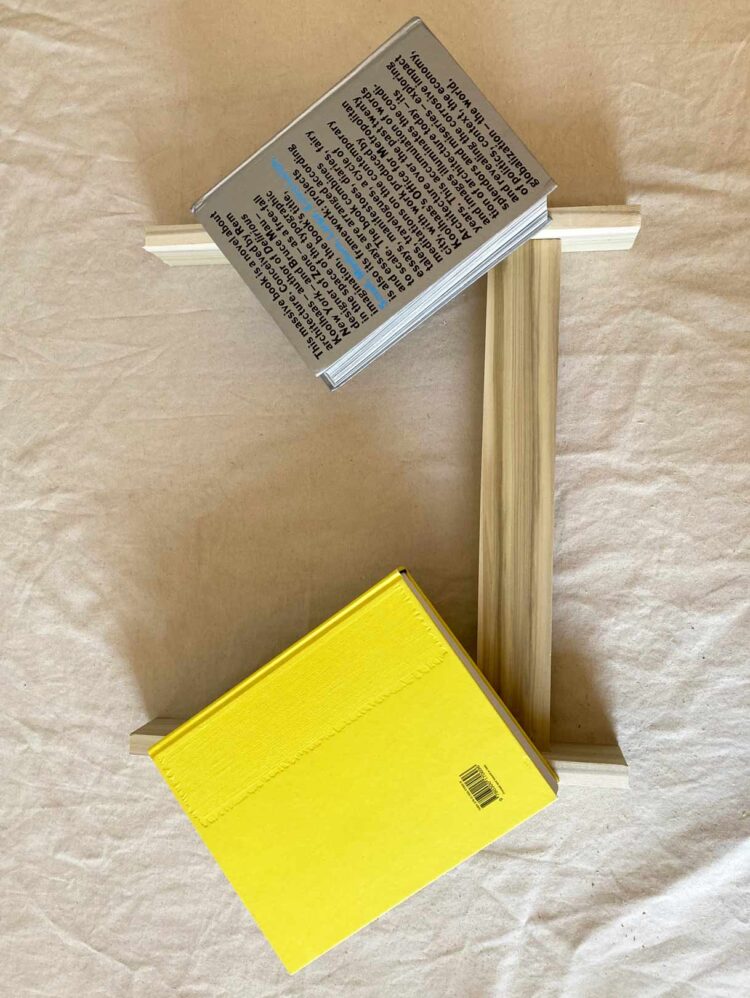

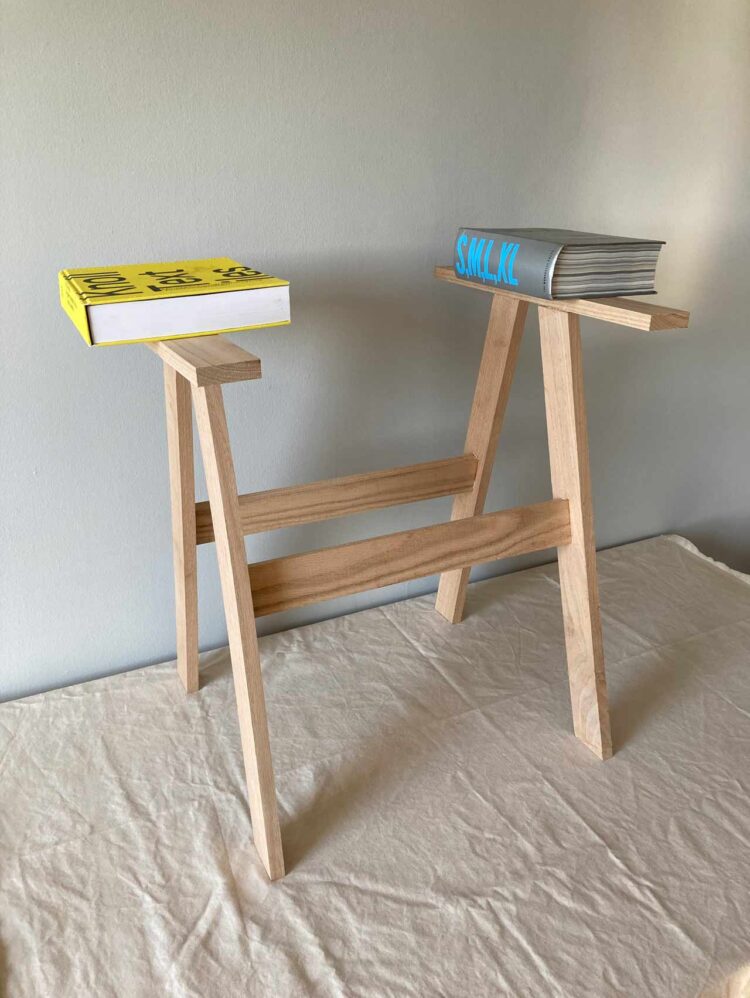

Simple Joinery Daybed

Design and photography by Ian Anderson

Published in Spring 2021

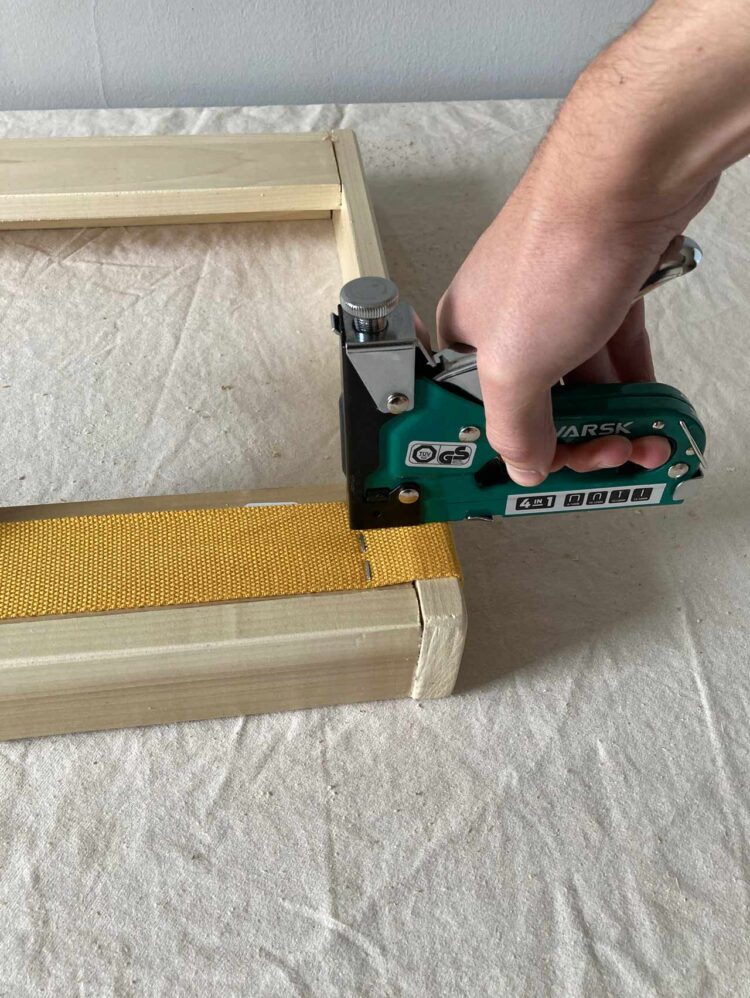

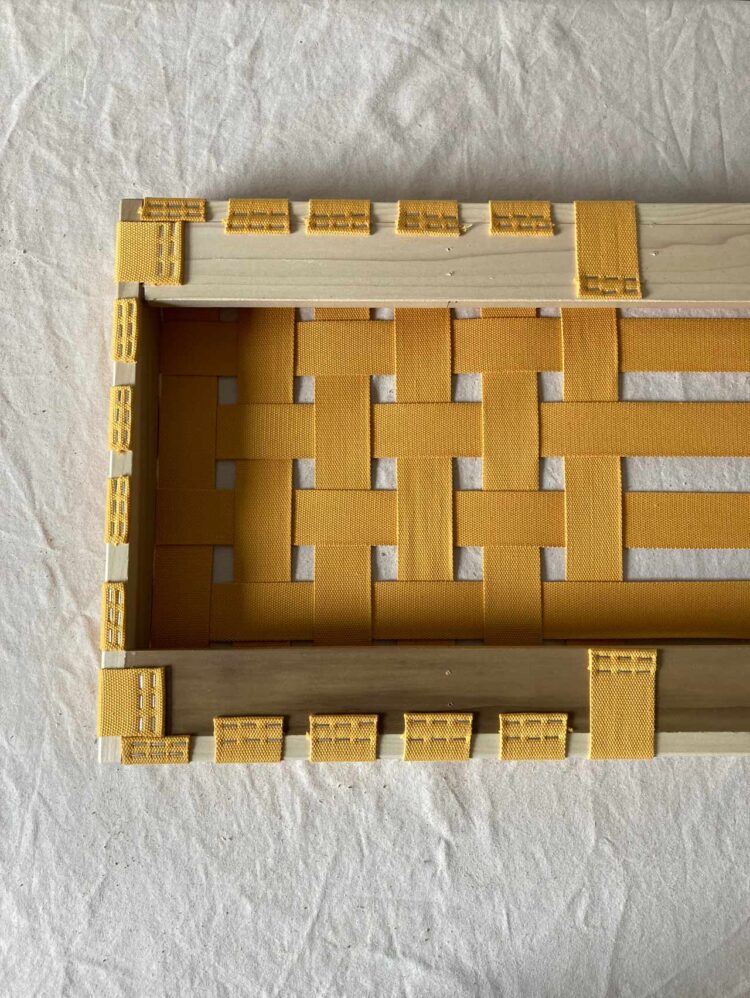

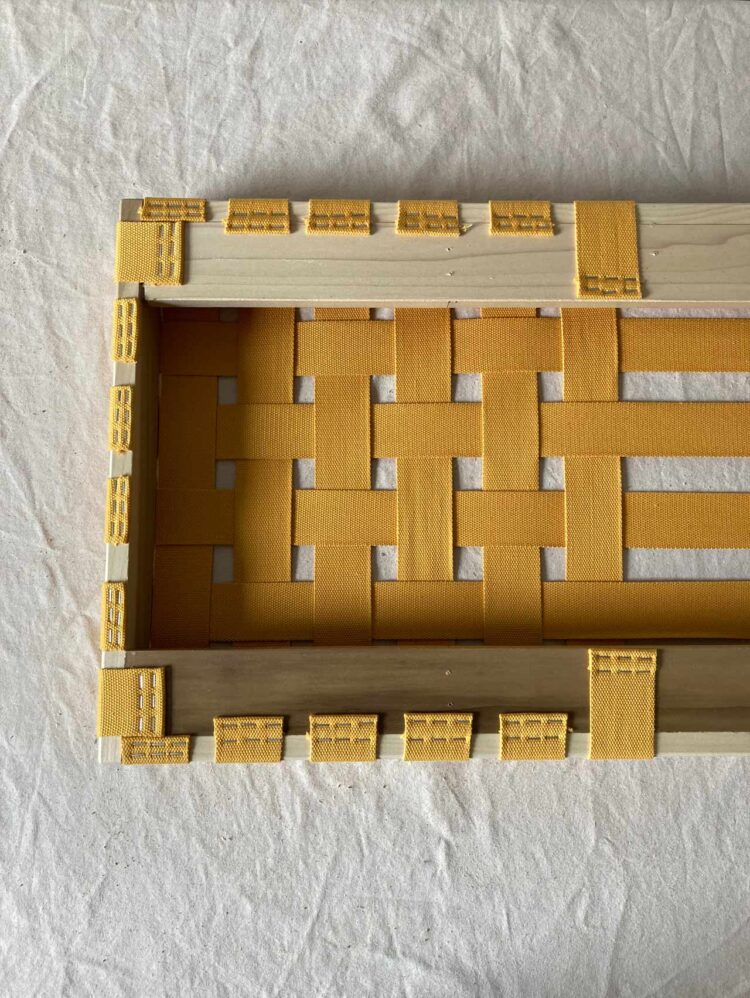

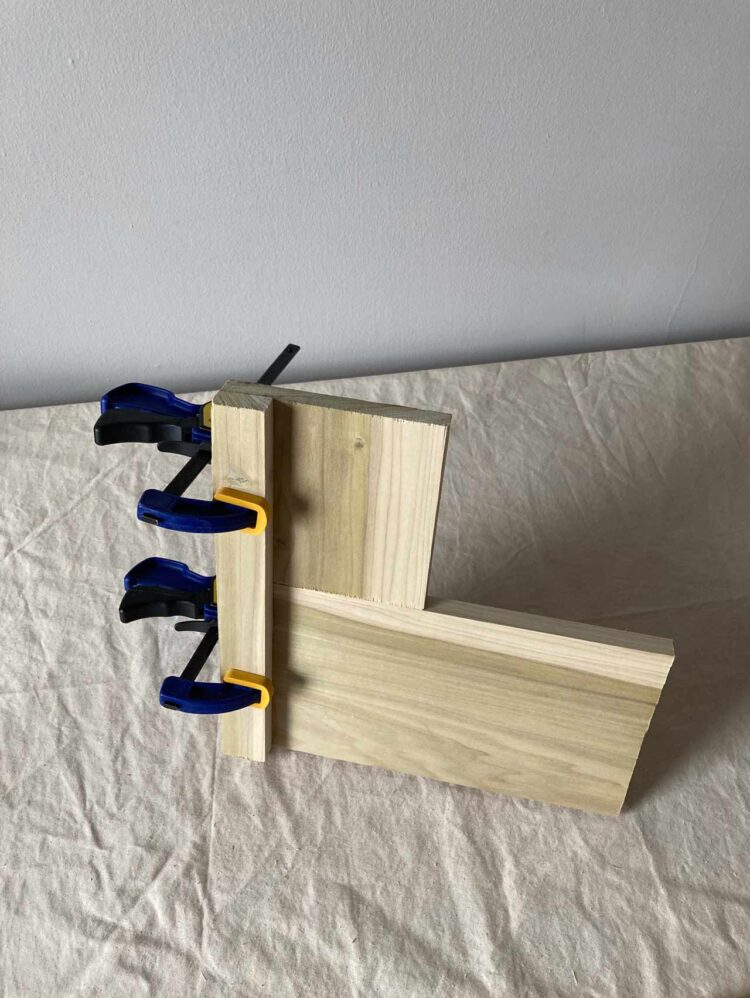

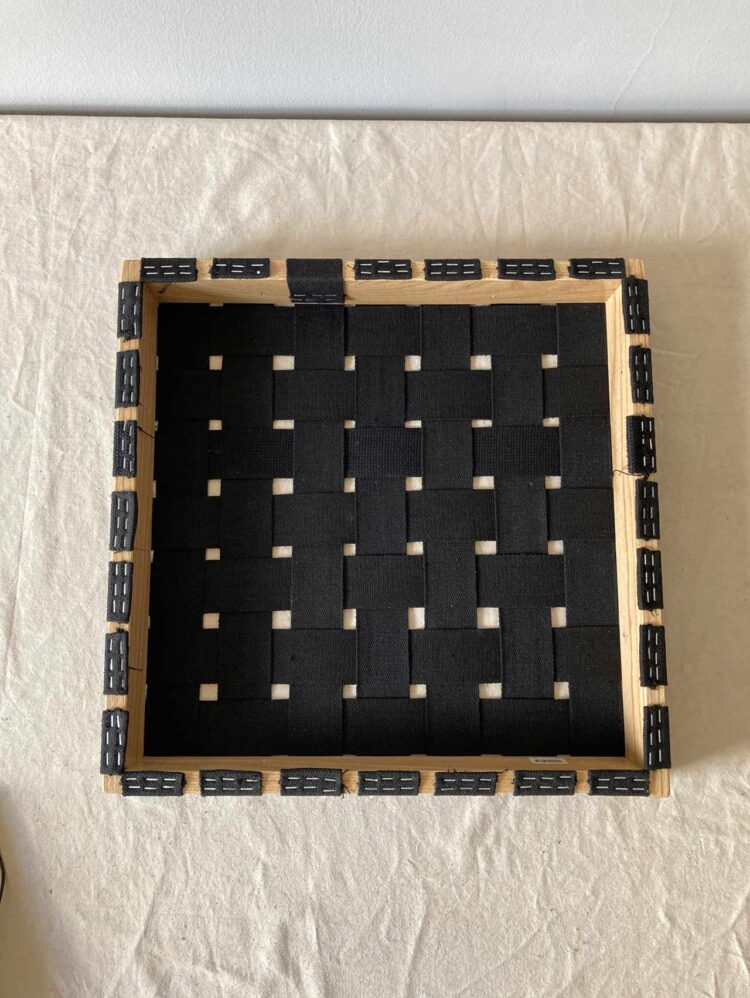

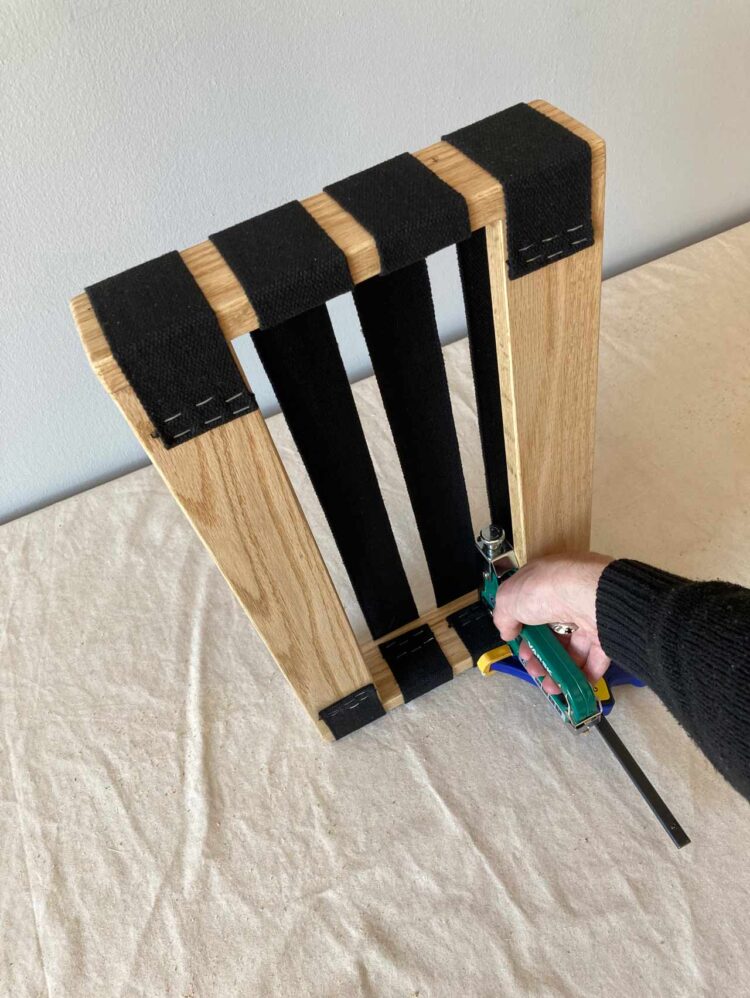

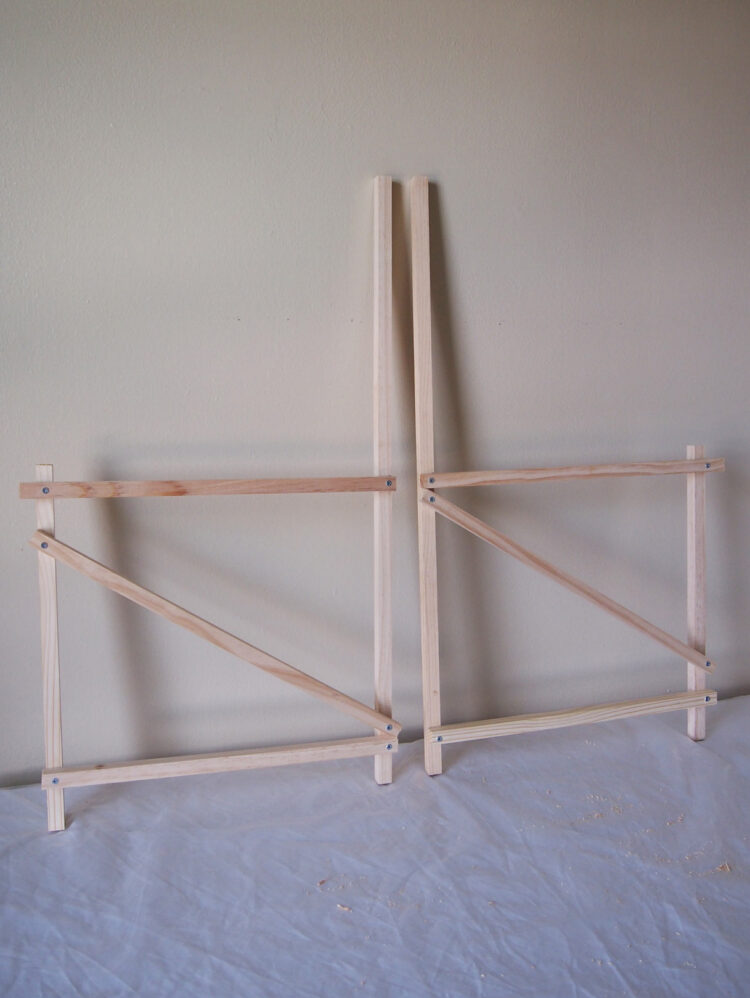

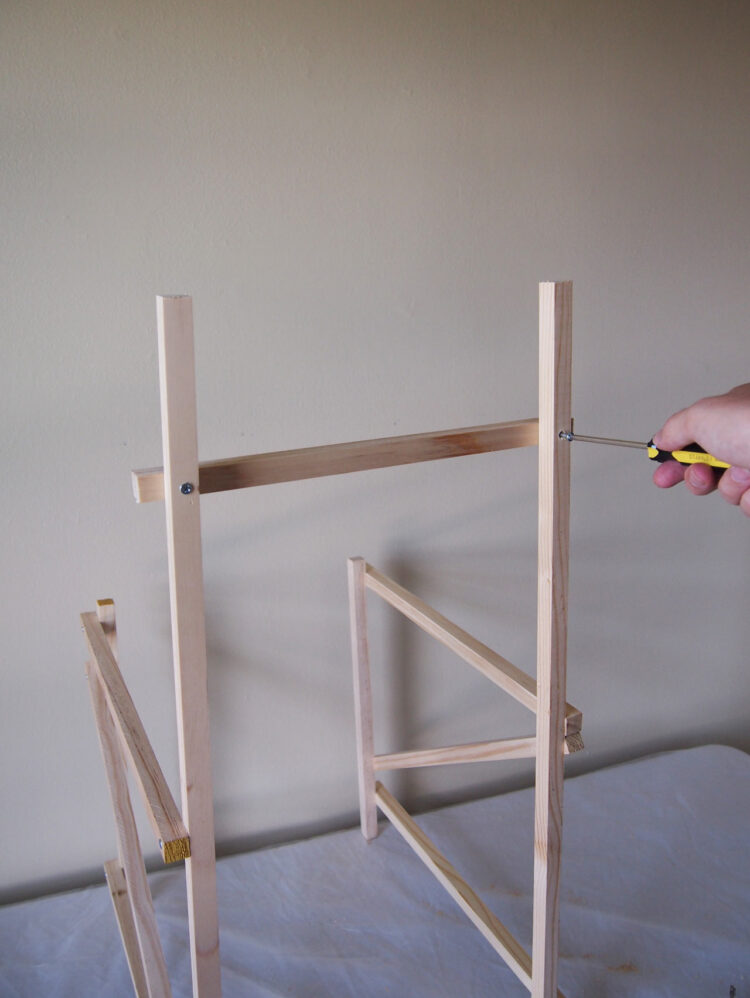

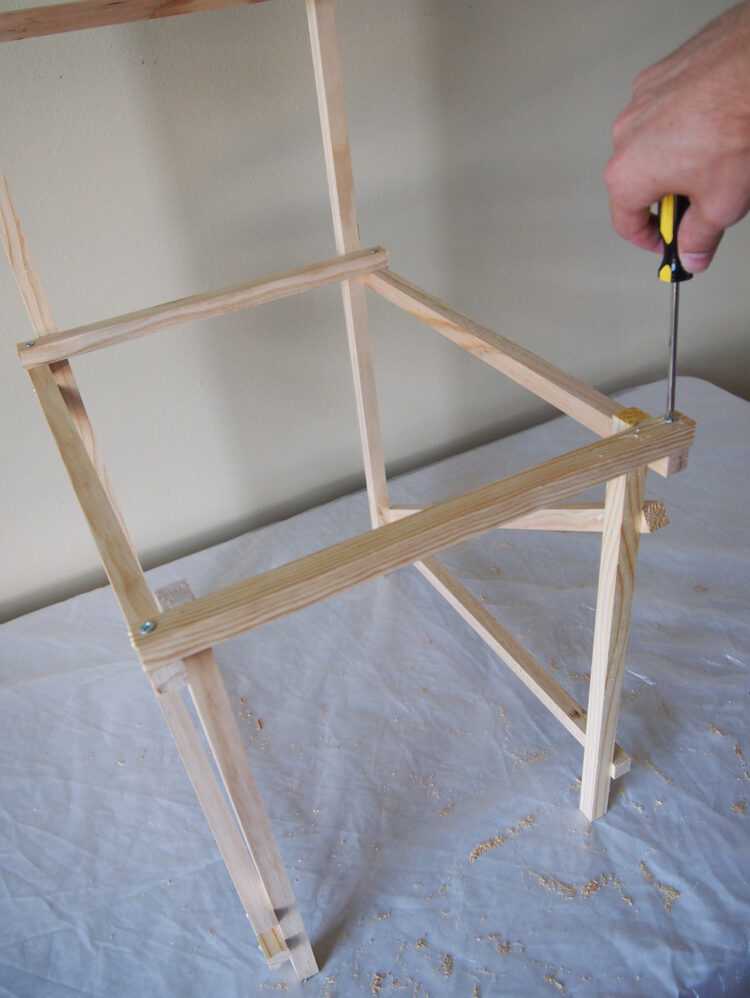

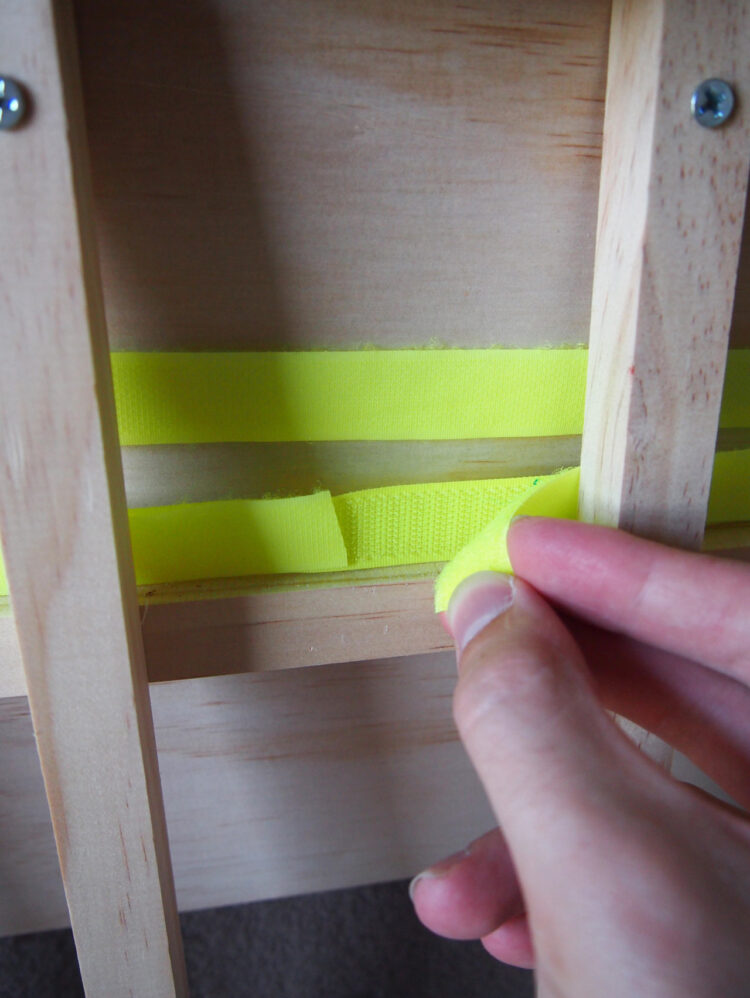

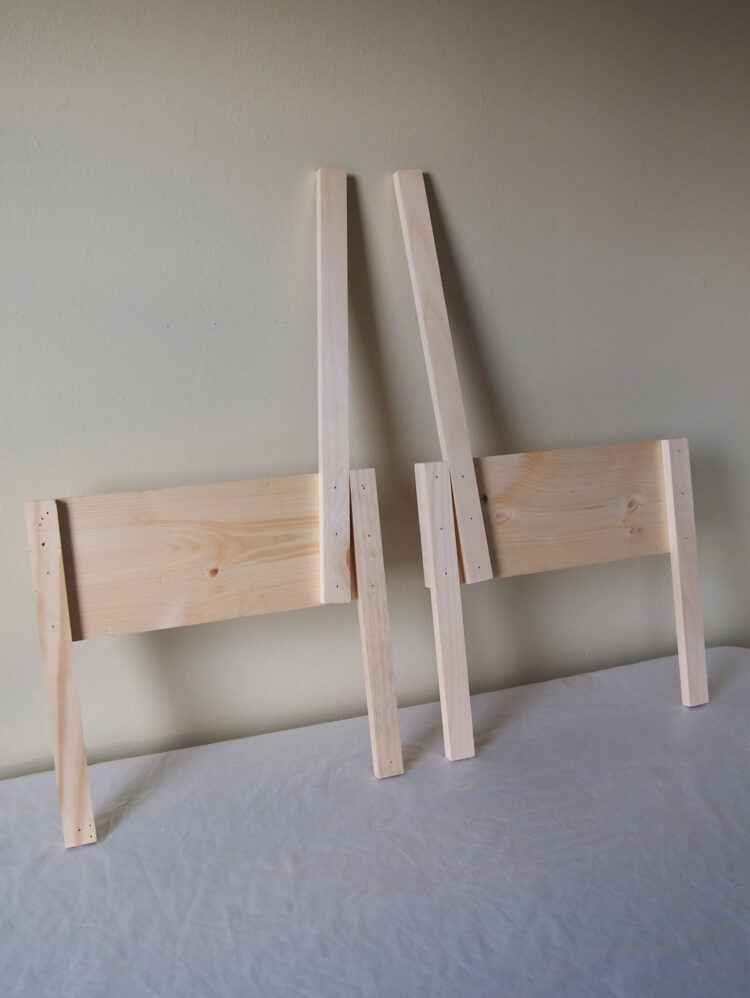

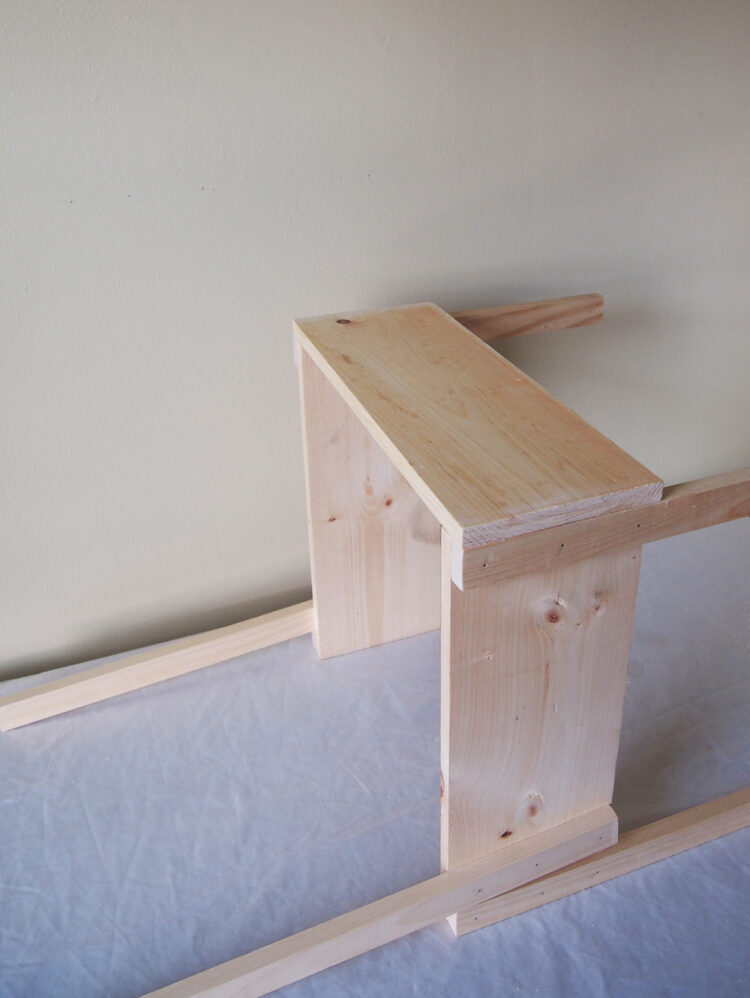

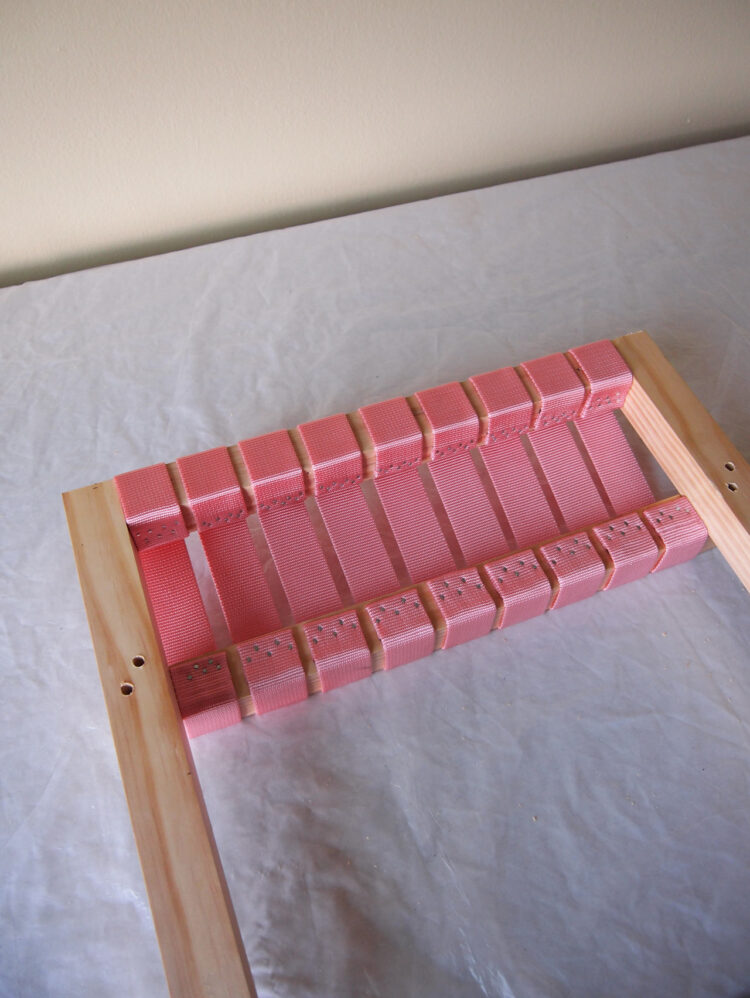

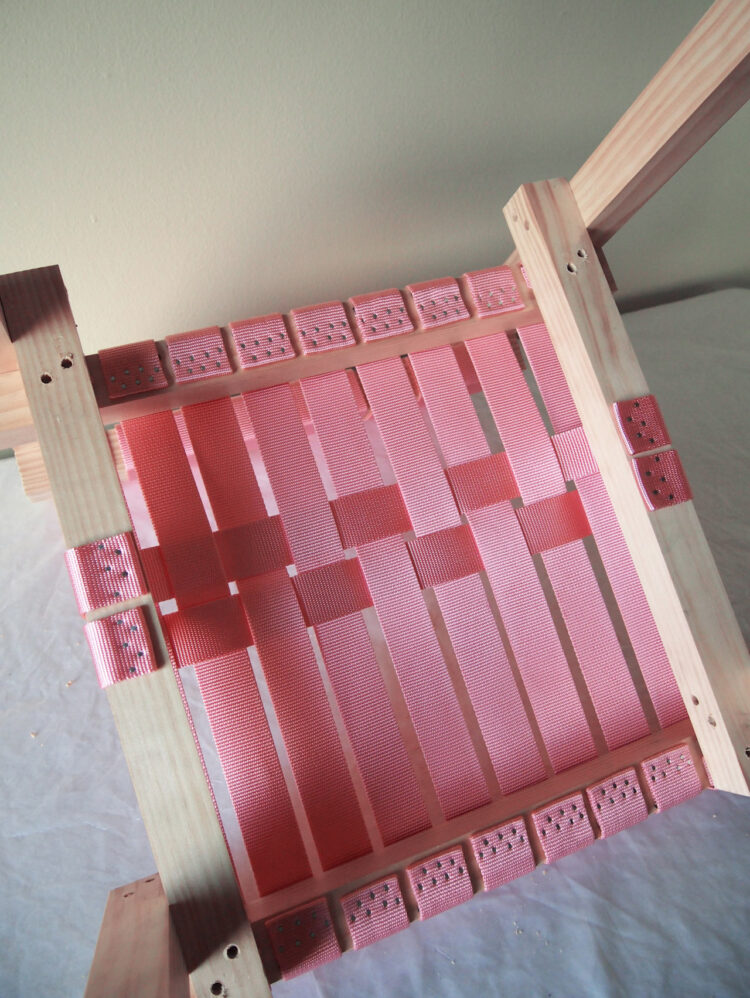

Sharing the same design as the Simple Joinery Long Bench, the assembly steps outlined below use modified instructions from the bench assembly. Much like a cot, the daybed utilizes tension straps in lieu of cushions. The timeless visual appeal and functionality of the canvas straps combine with the efficient engineering of reinforced wood joinery in this design. As with all of the Simple Joinery designs, the challenging assembly takes about 1-2 days to complete.

Assembly

Index

Parts

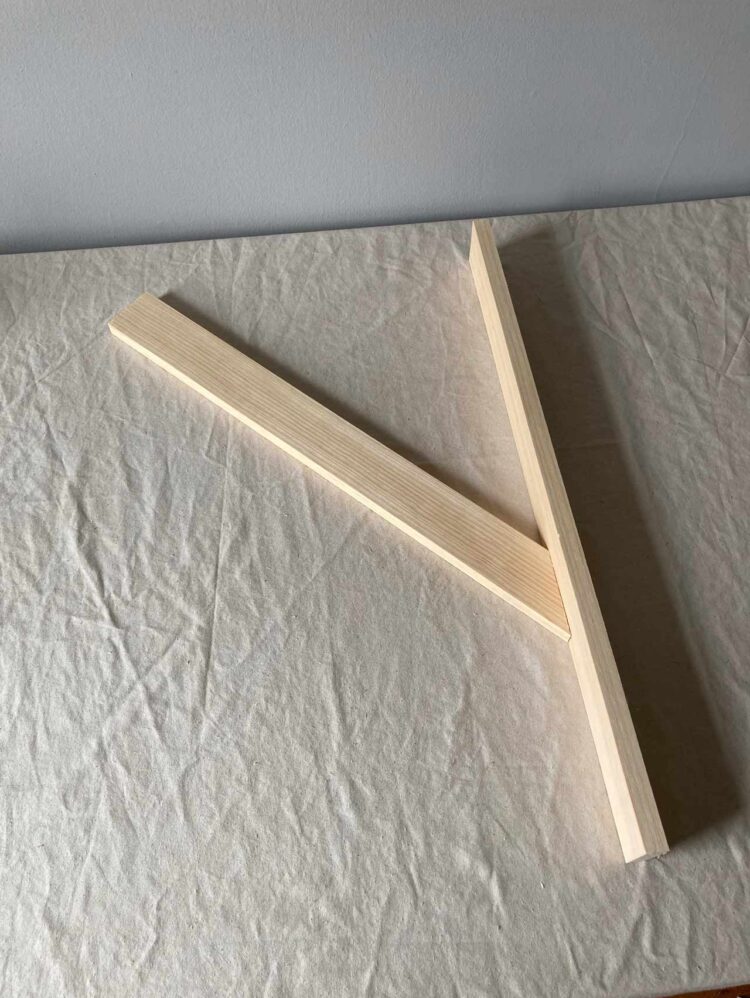

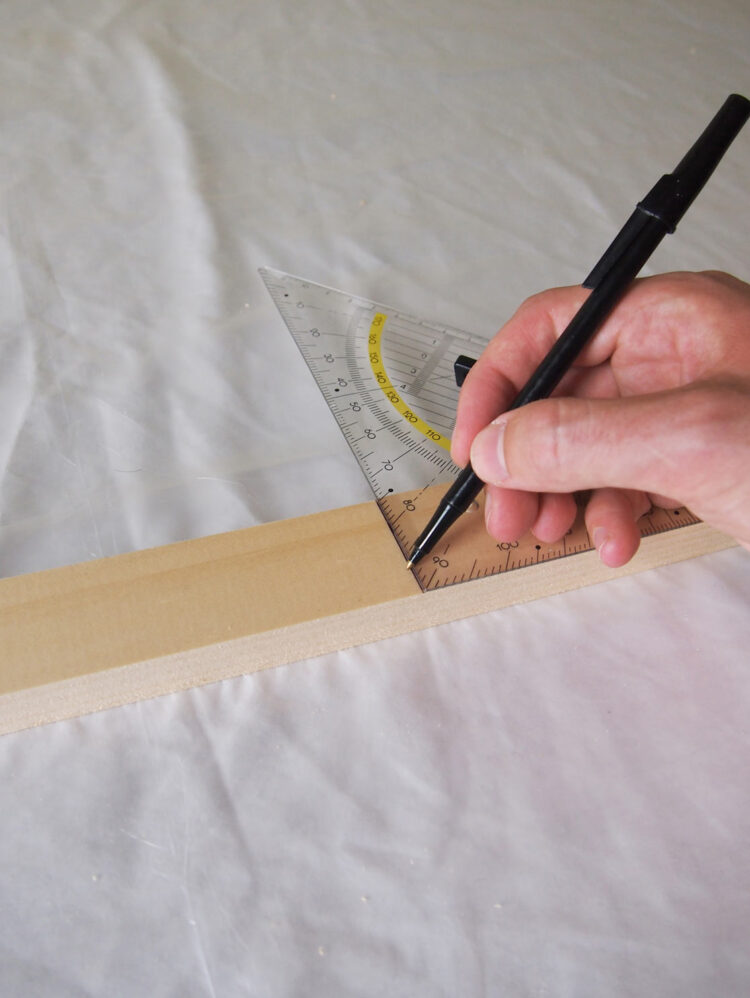

Smooth Planed Poplar Wood, 1in x 4in (20.5mm x 95mm)

*Any popular hardwood can be used, like Poplar, Birch, Beech, Cherry, and Oak. Softer hardwoods like Cherry and Poplar are recommended. Metric measurements above are actual, not nominal.

Quantity required: 4 pieces 77in (196cm) long, 4 pieces 39in (99cm) long

Smooth Planed Poplar Wood, 1in x 3in (20.5mm x 70mm)

Quantity required: 4 pieces 17.5in (44cm) long, 2 pieces 22in (56cm) long

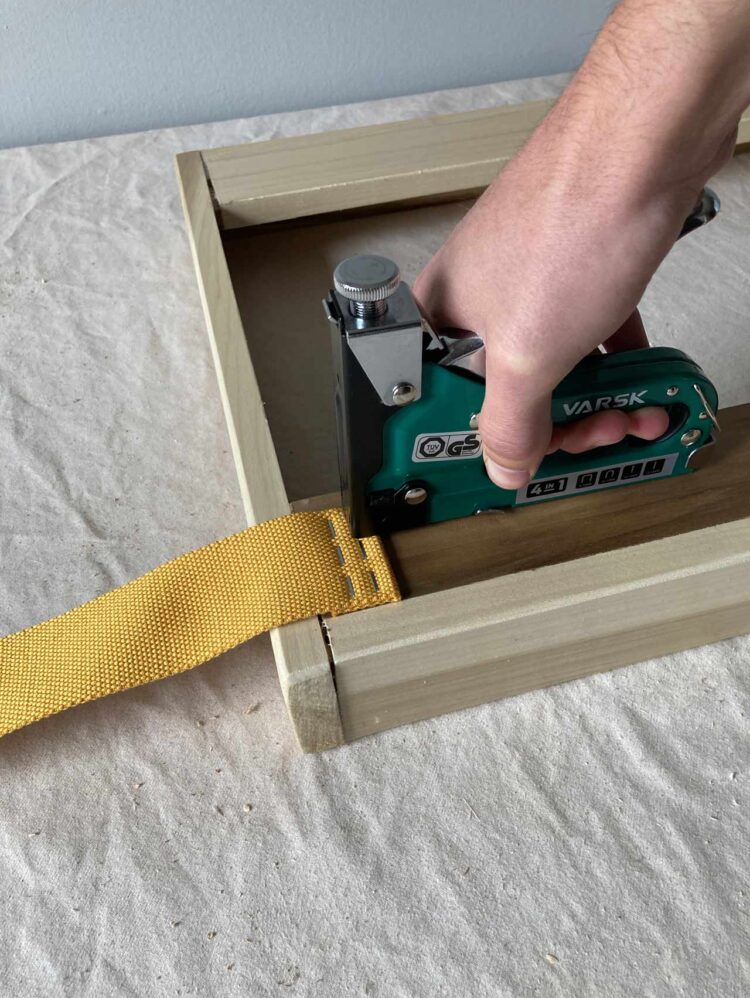

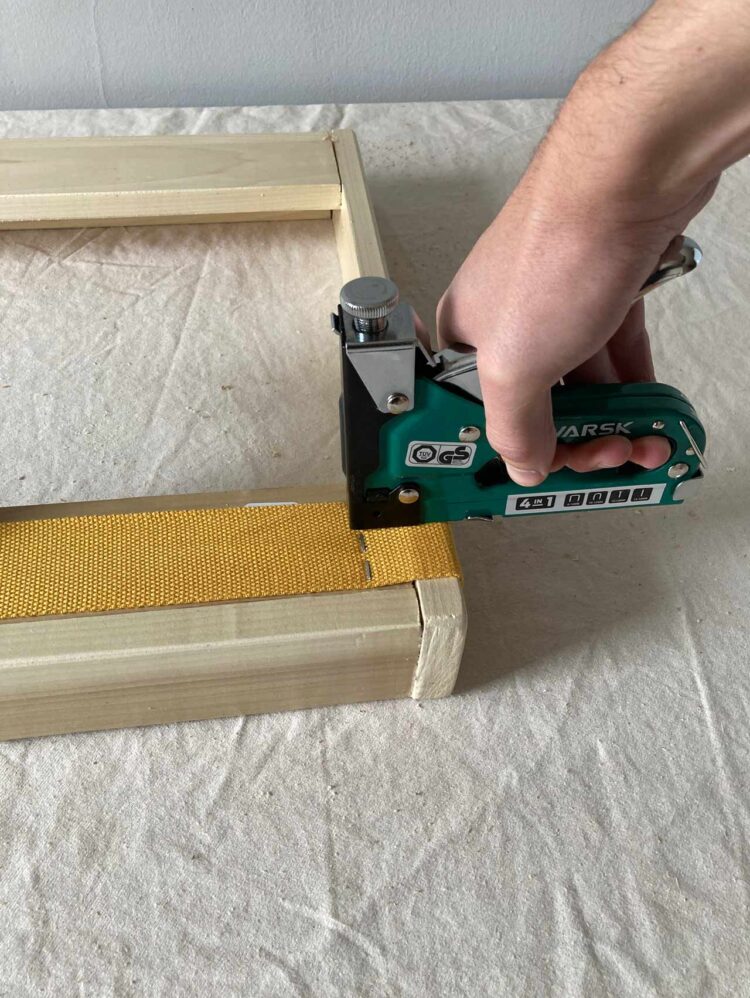

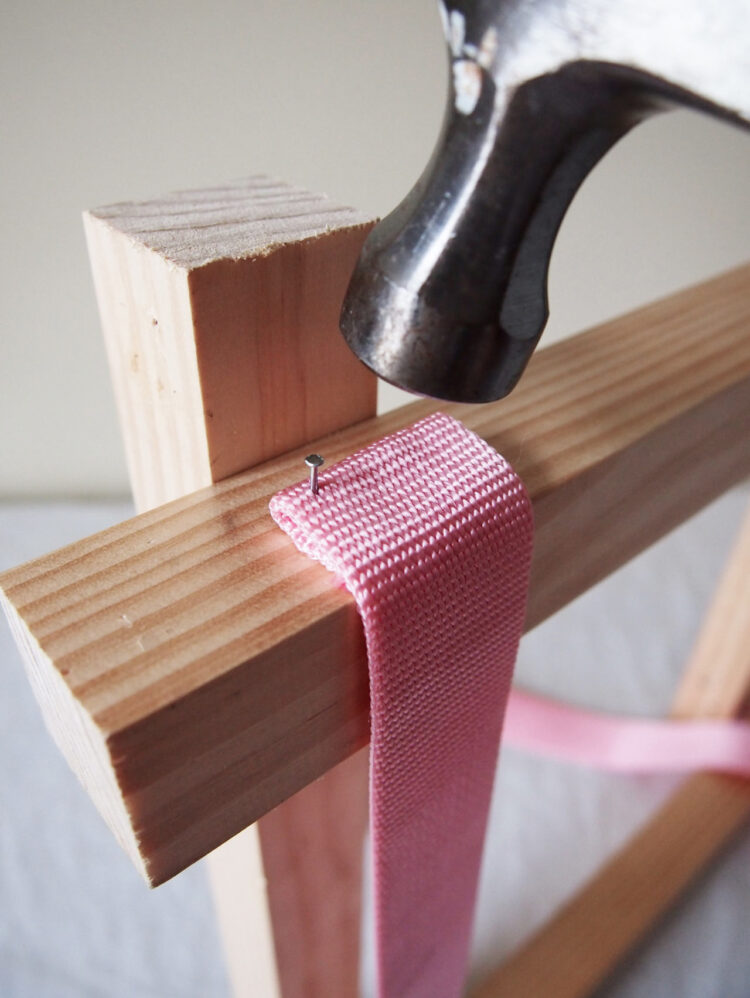

Heavyweight Cotton Webbing, 2in (50mm) width, 2mm thick

Quantity required: 50 yards (46 meters)

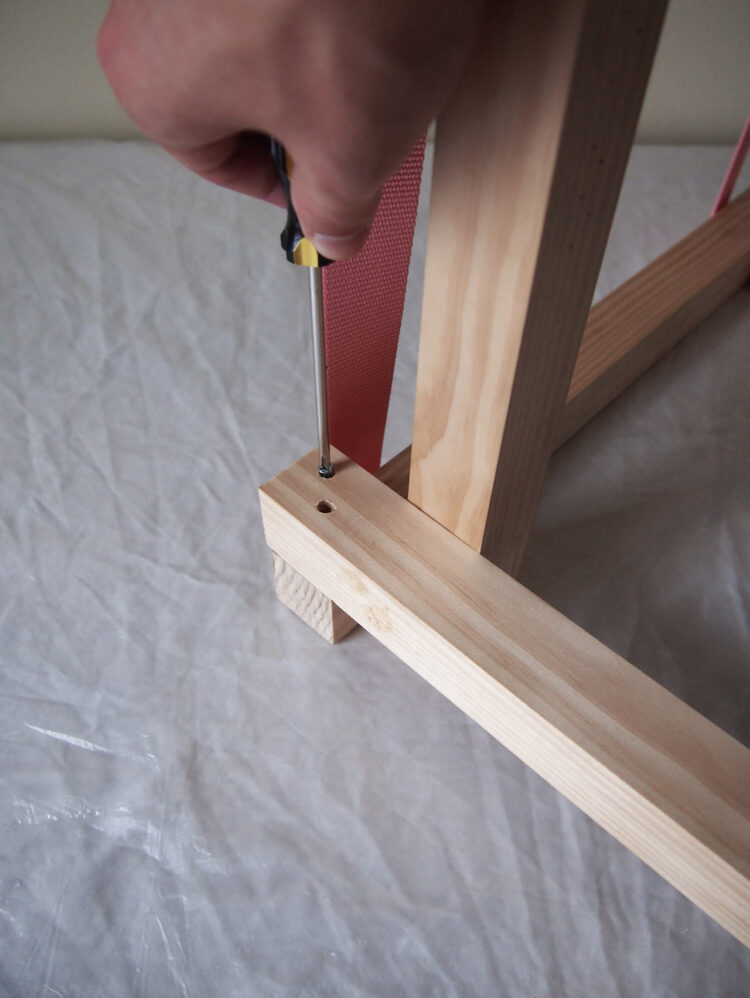

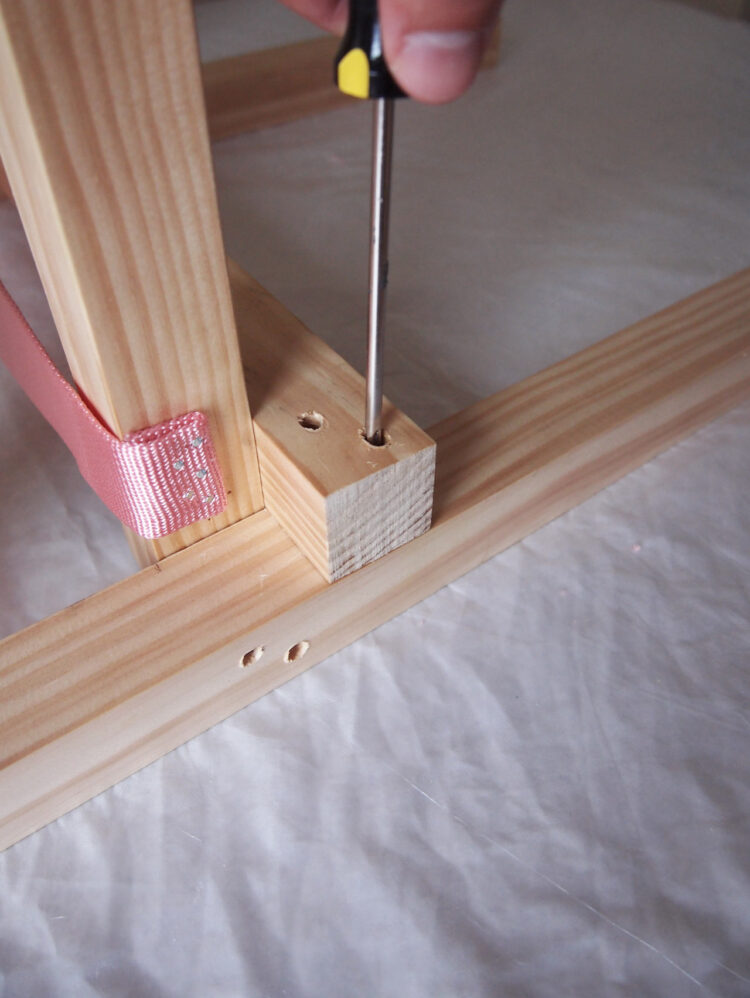

Flat Head Wood Screws, #6 x 1-1/2in (4 x 35mm)

Quantity required: 24

Tools

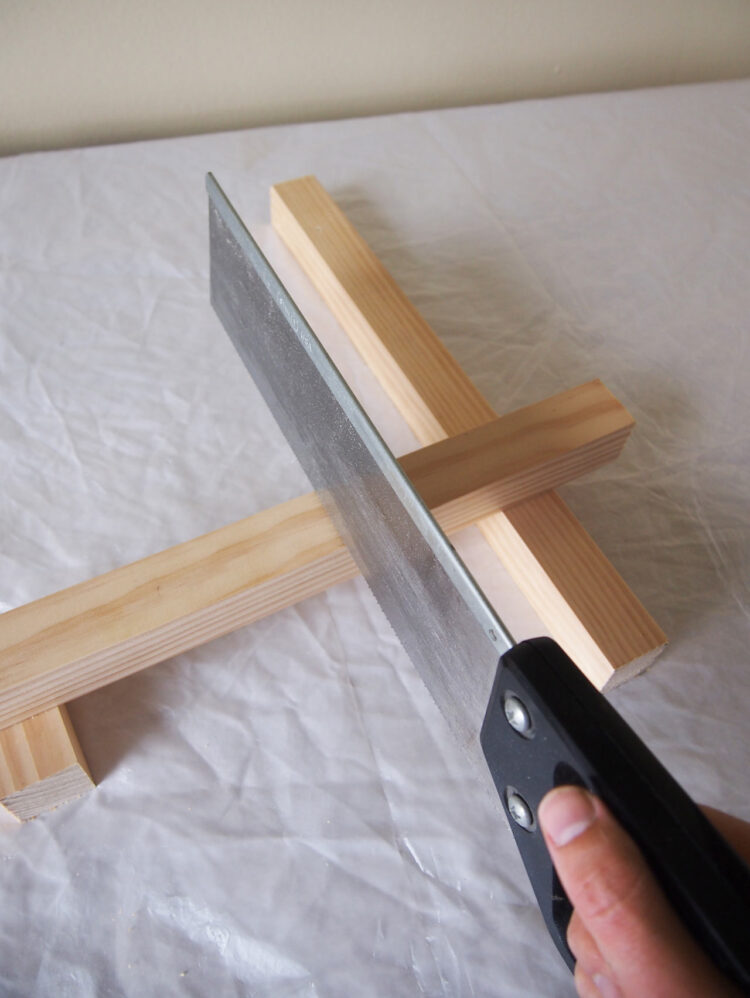

Hand Saw

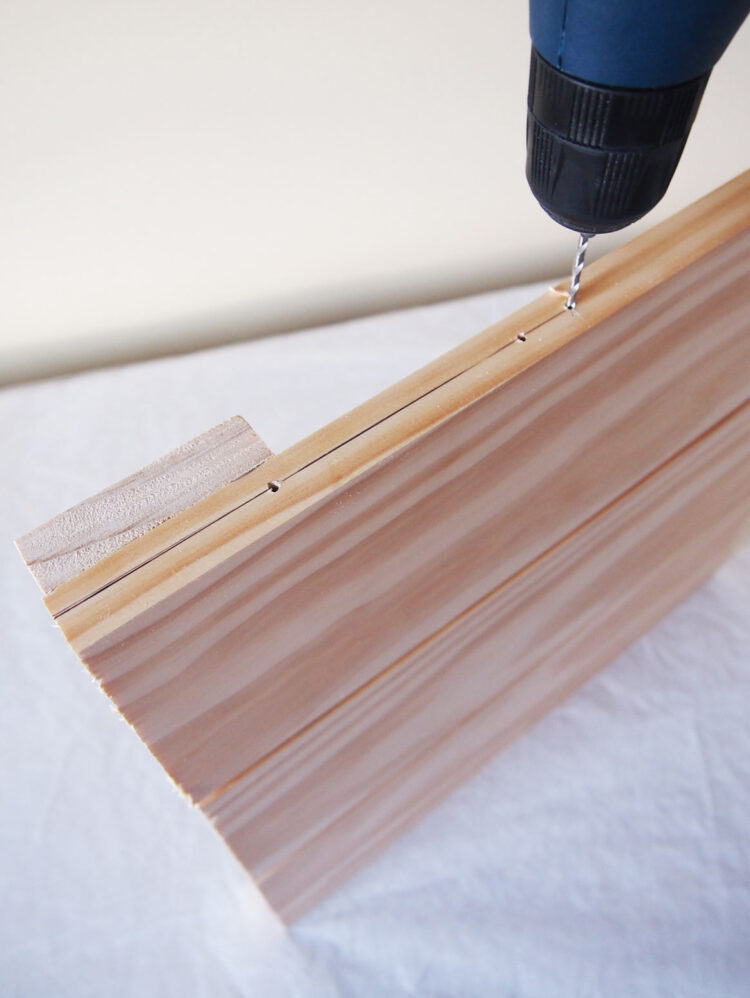

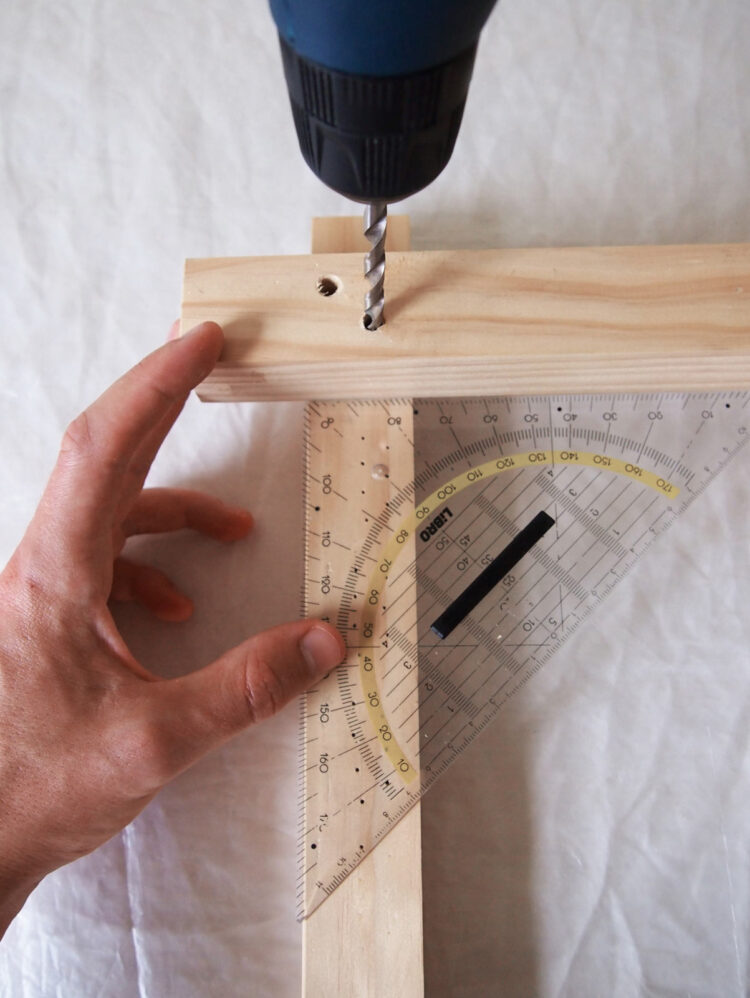

Power Drill

Drill Bits

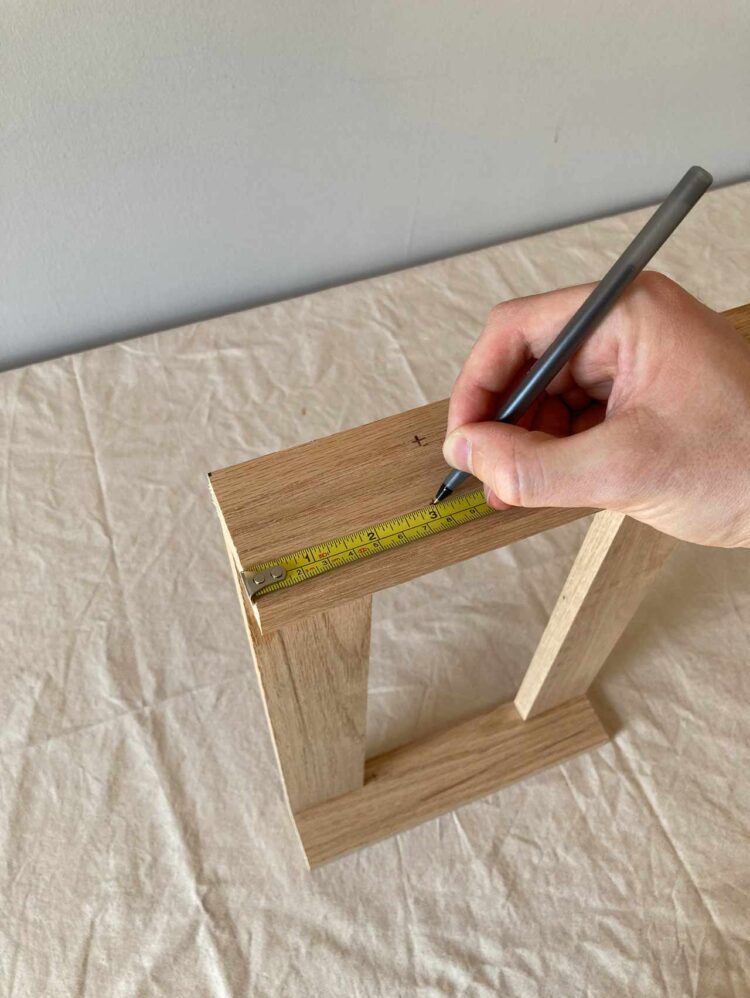

Ruler or Tape Measure

Screwdriver

Wood Glue

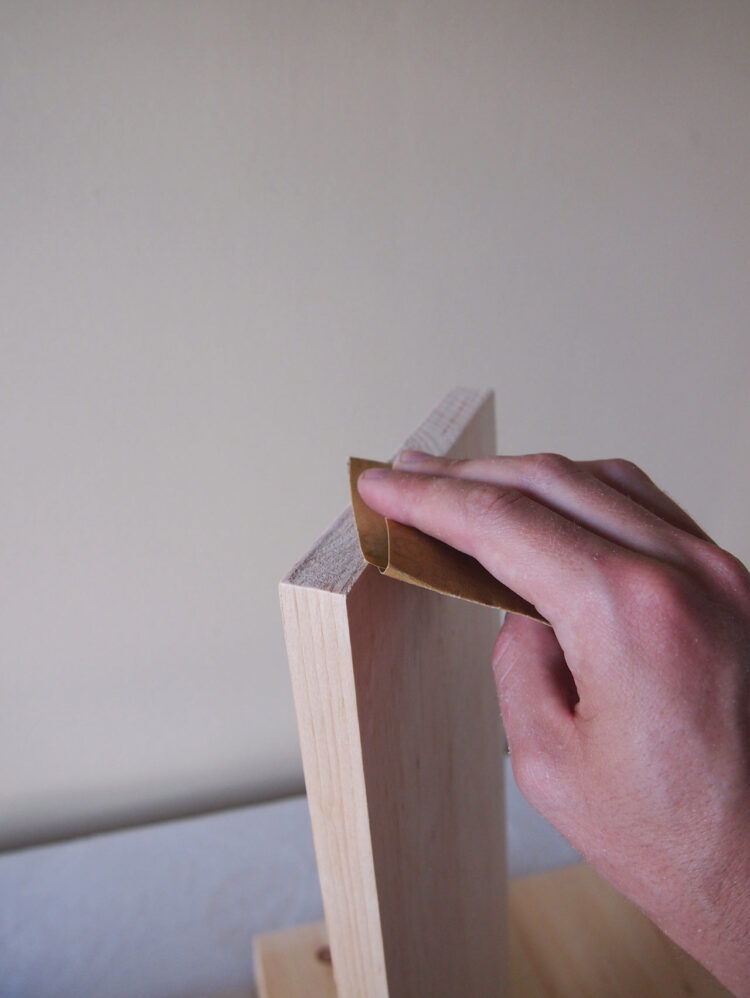

Sandpaper, 180 Grit

Heavy Duty Upholstery Staple Gun w/ Staples

Help Each Other