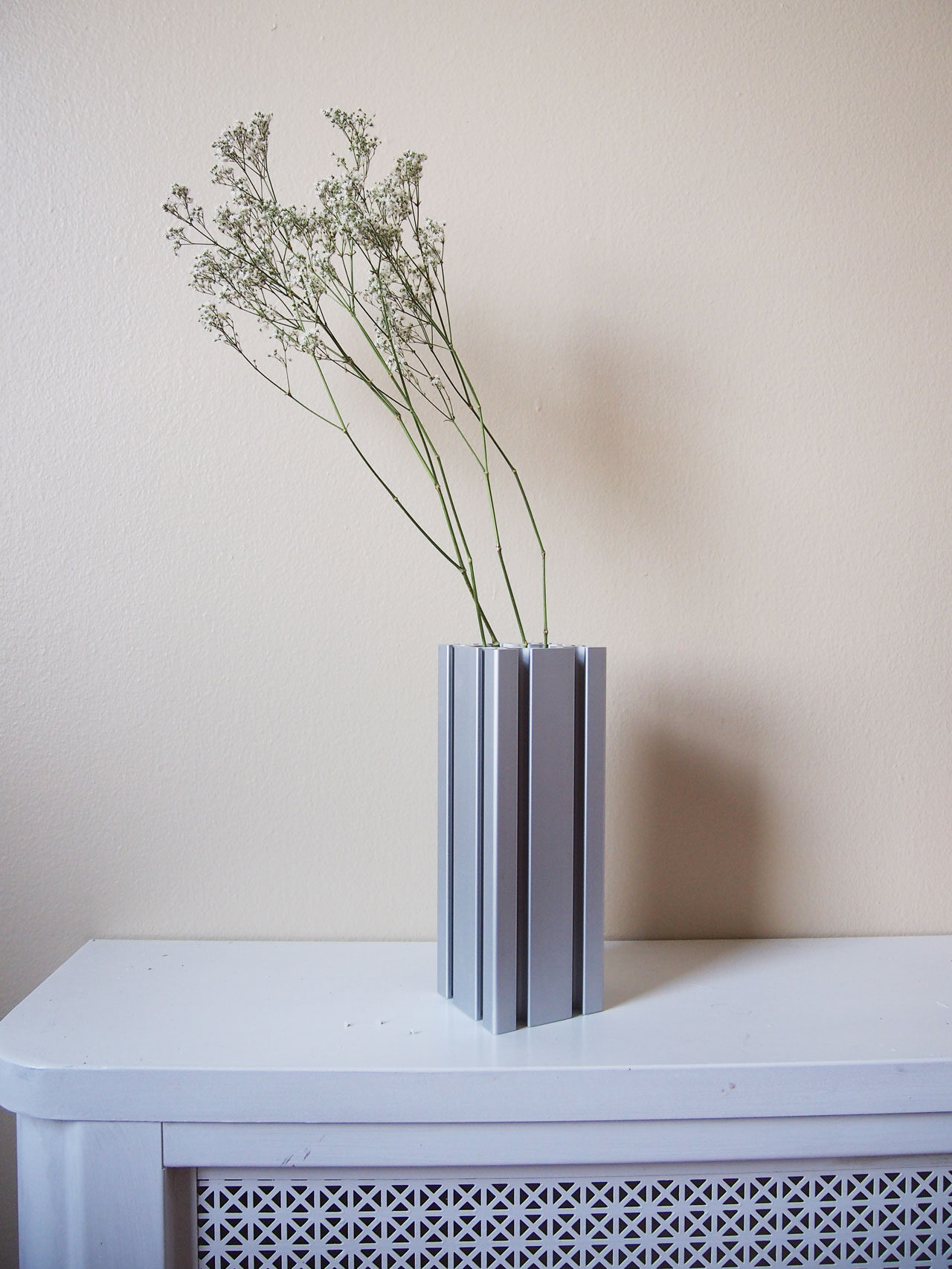

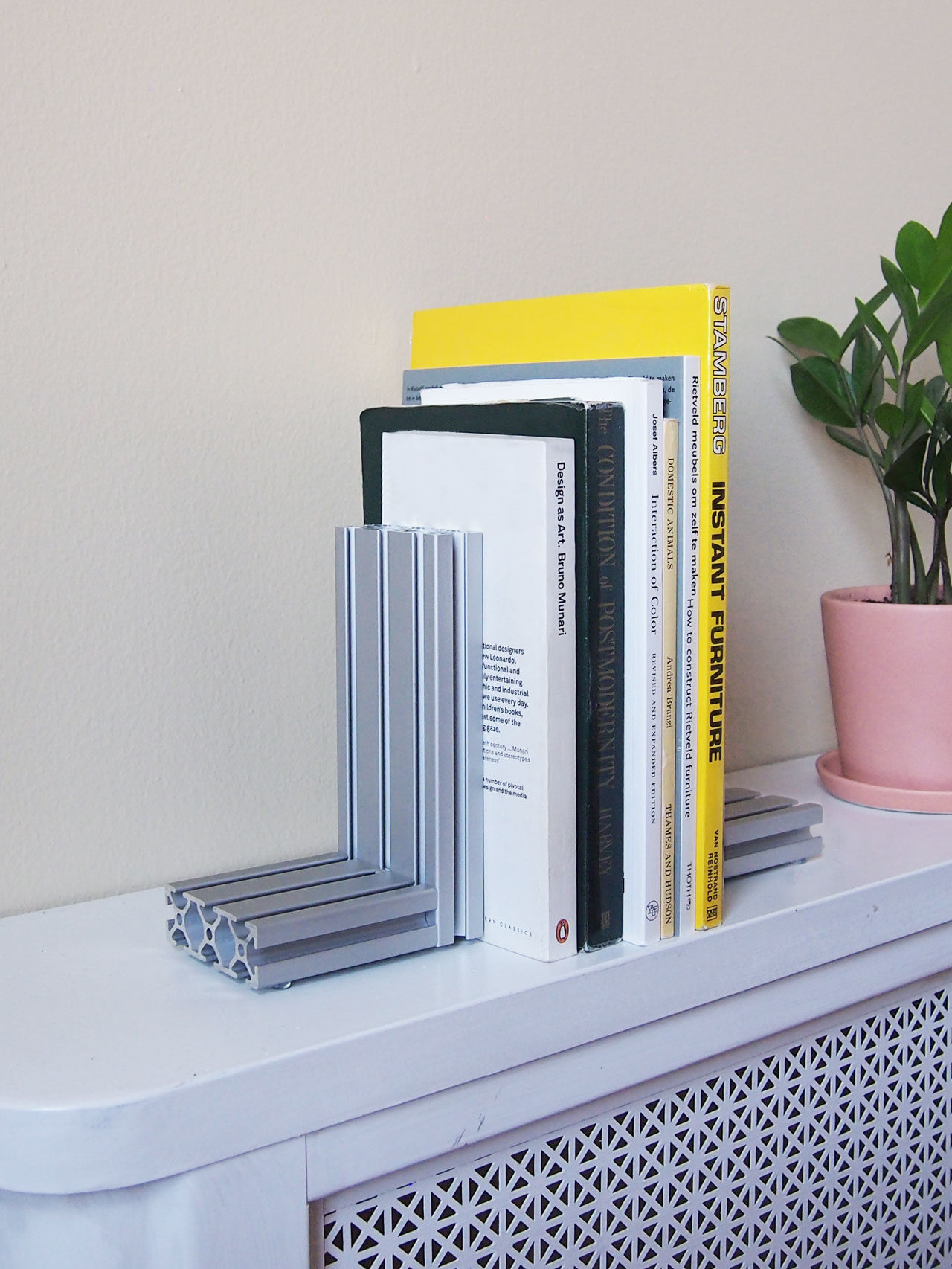

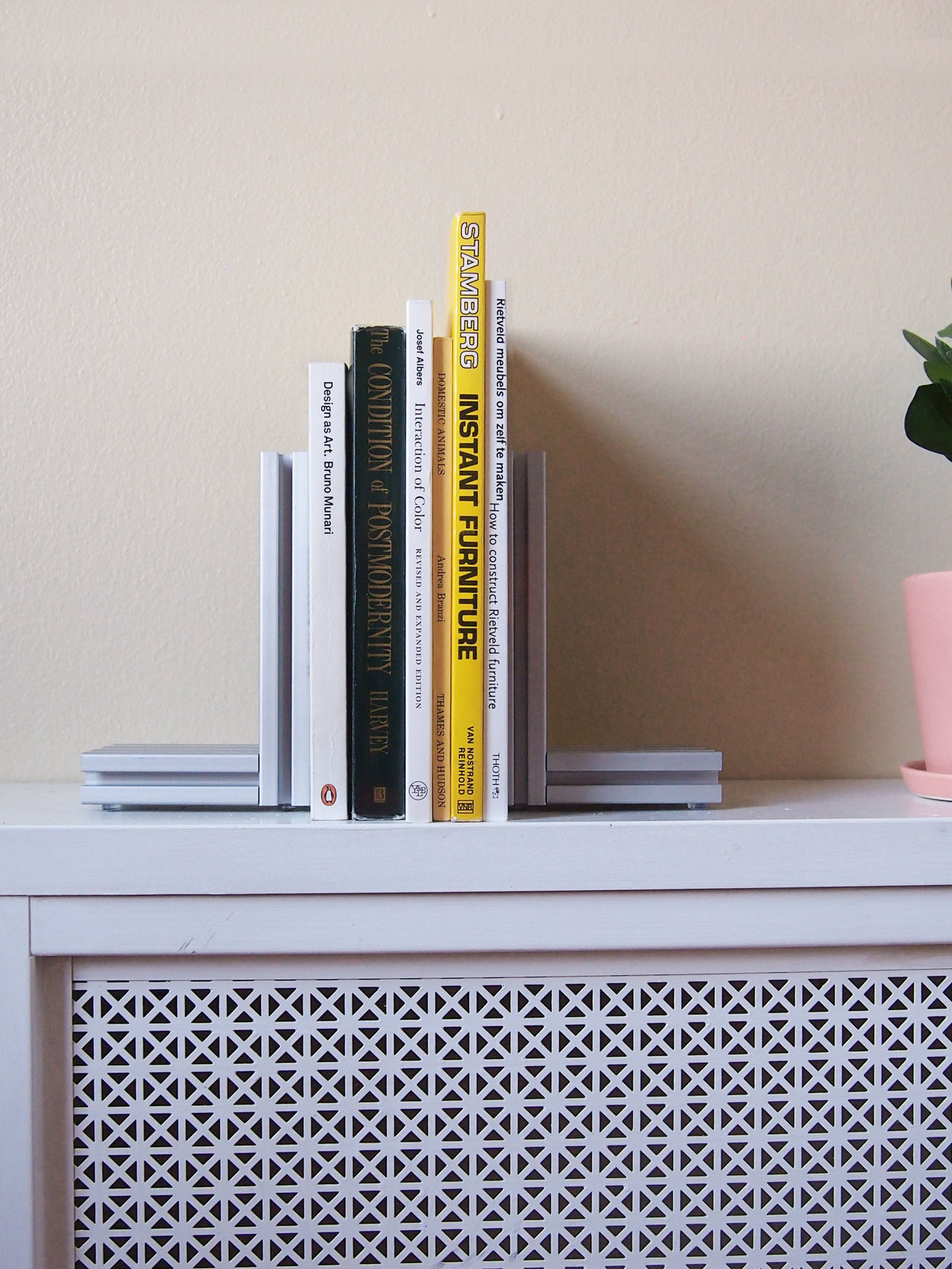

Utility Pendant Light

Design and photography by AANDERSSON

Published in Spring 2019

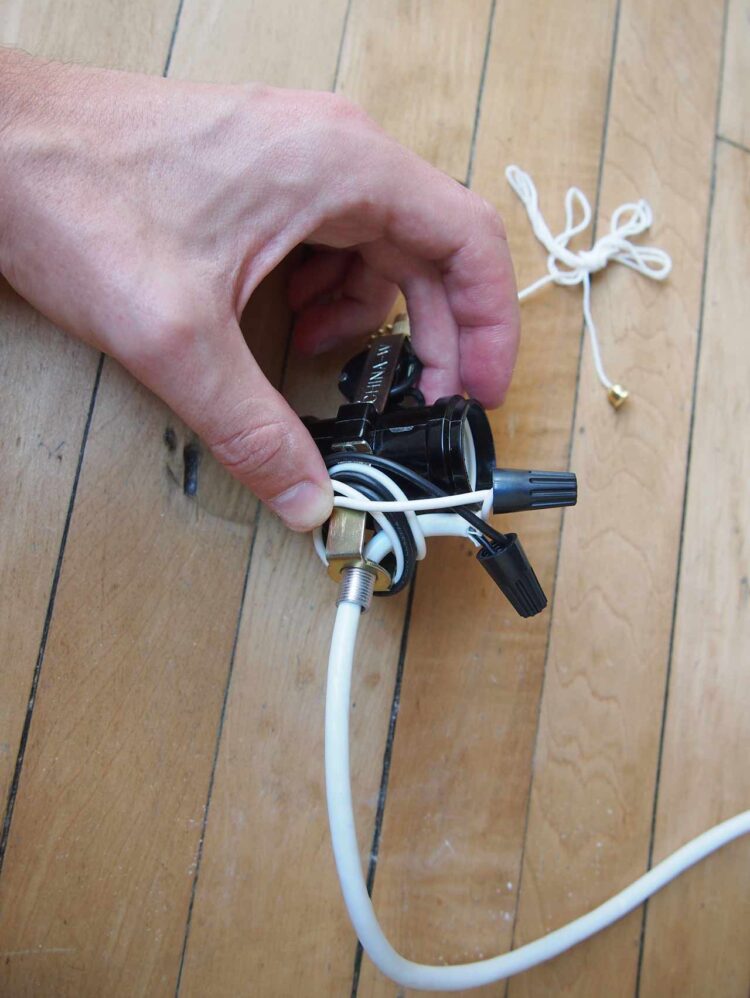

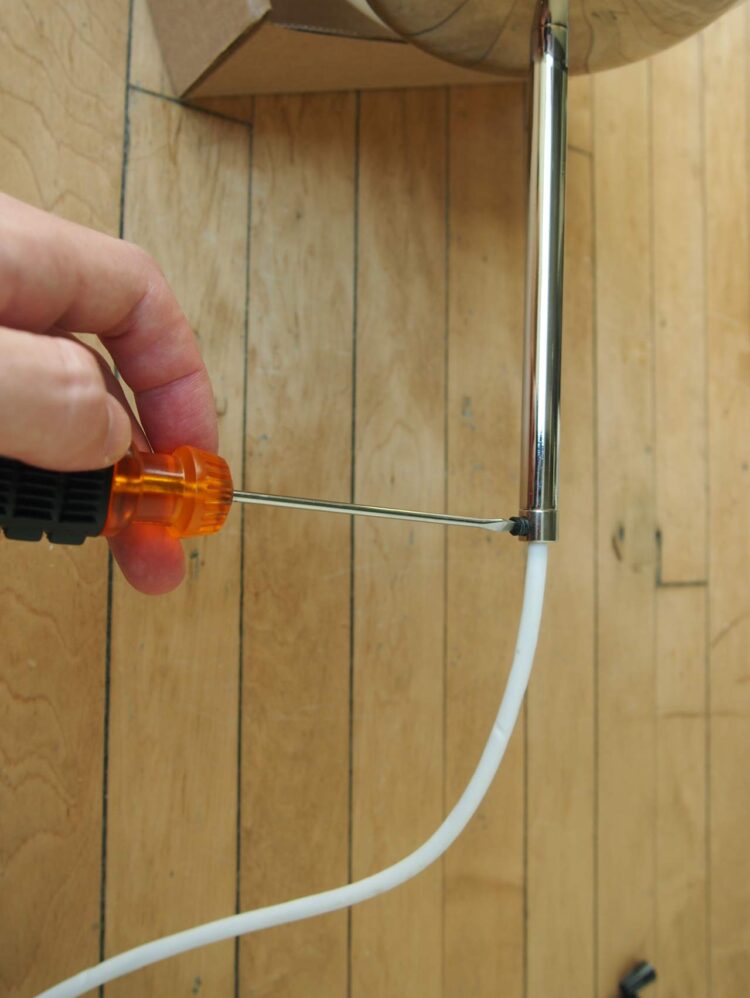

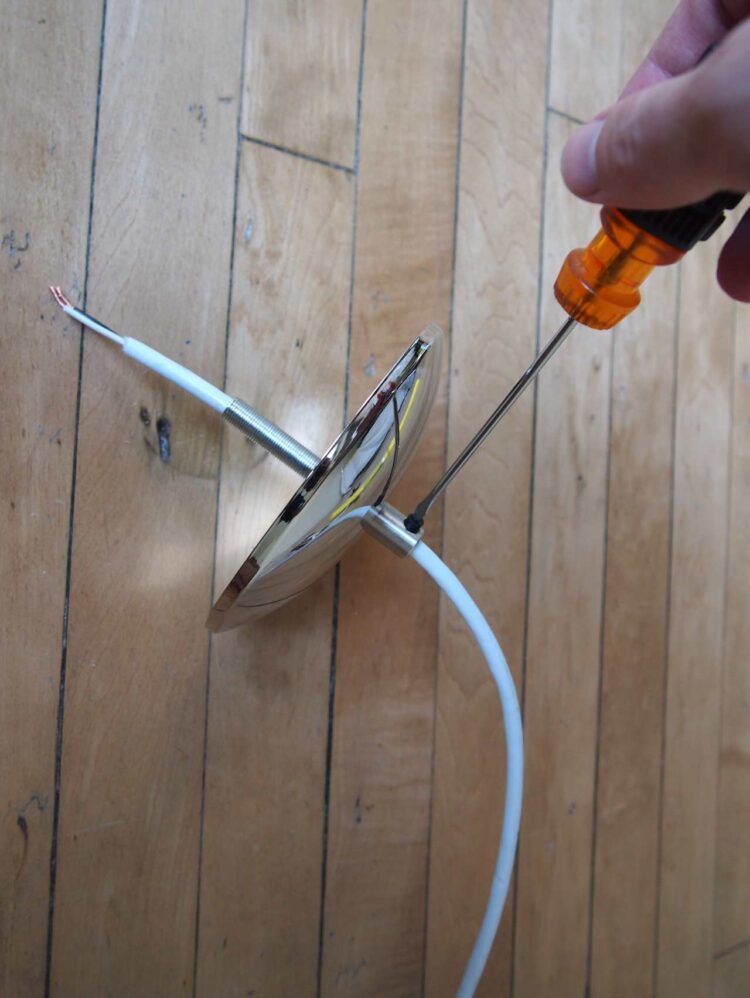

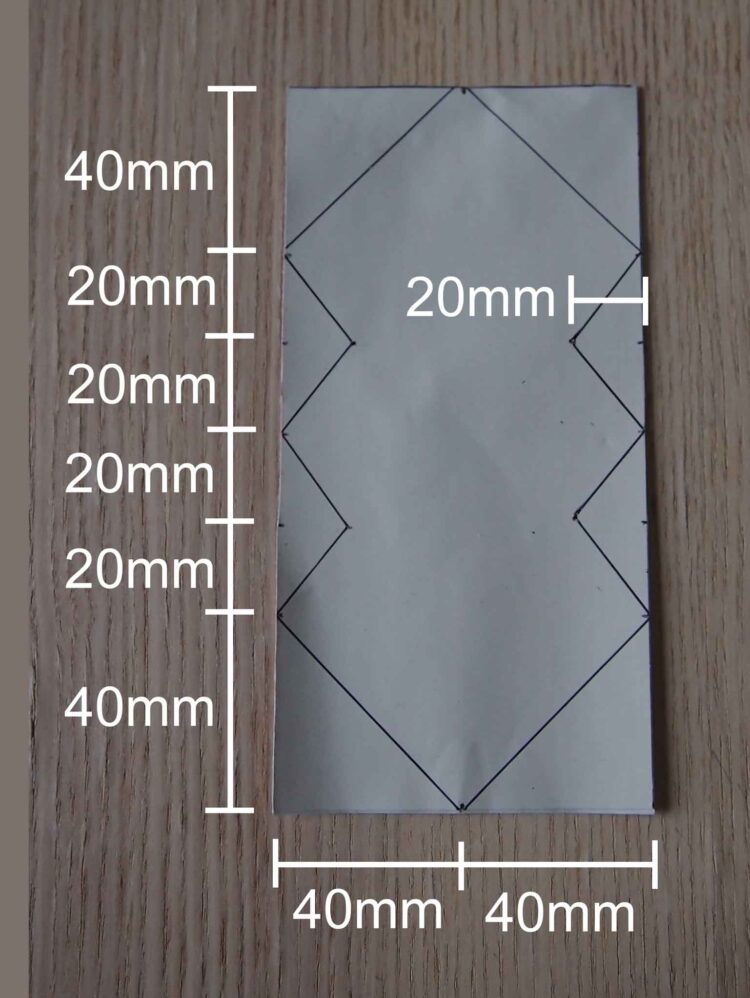

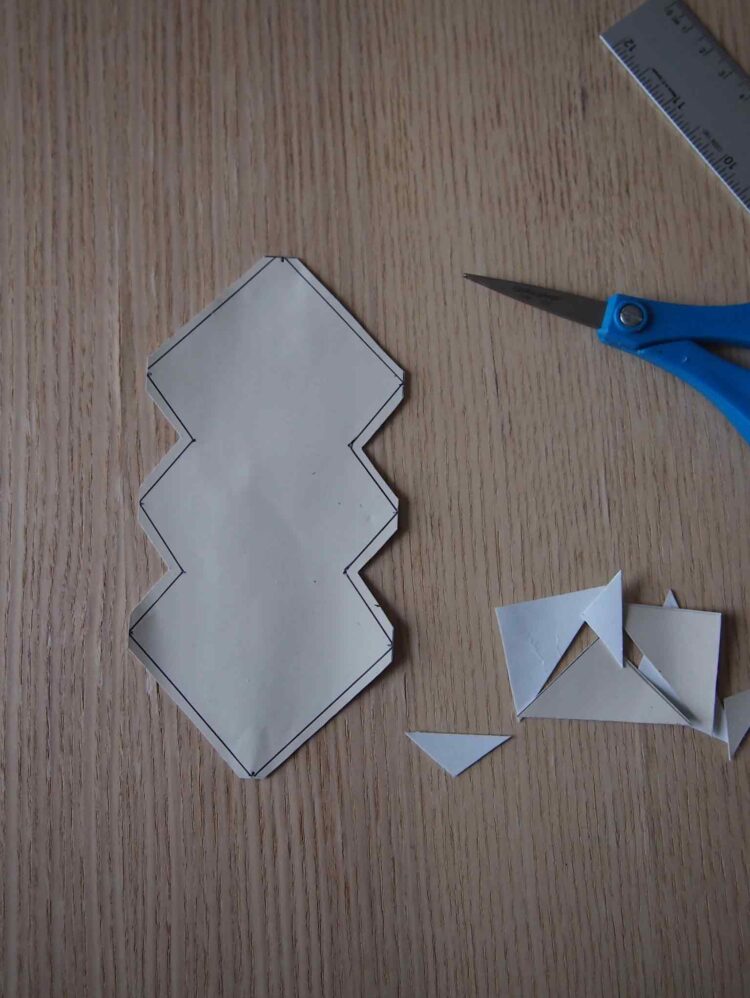

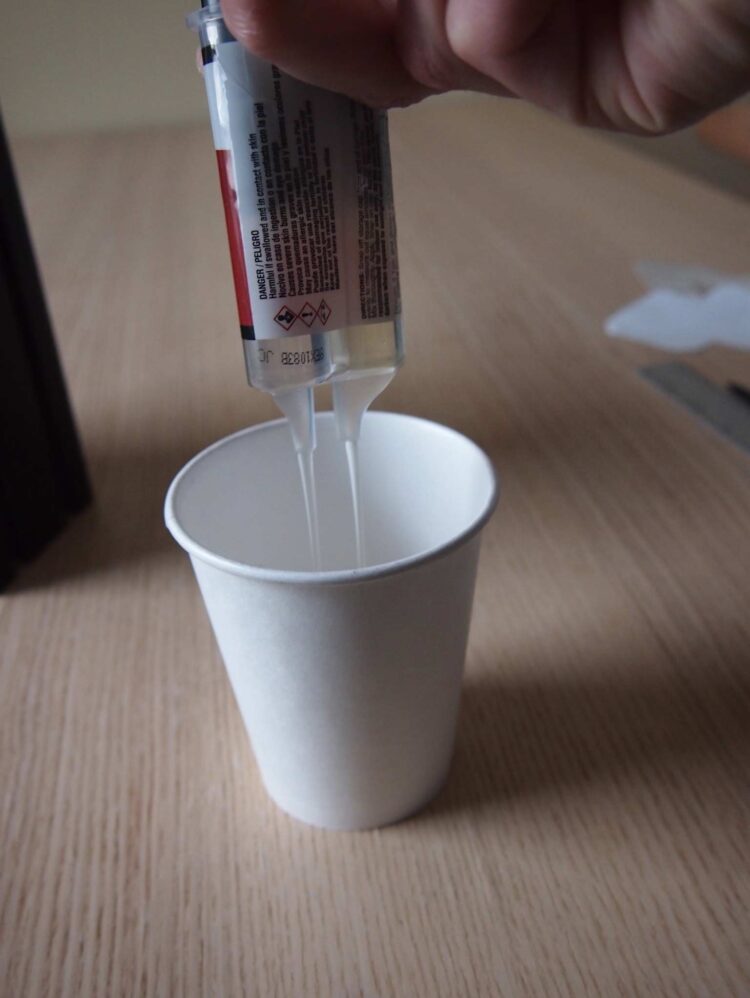

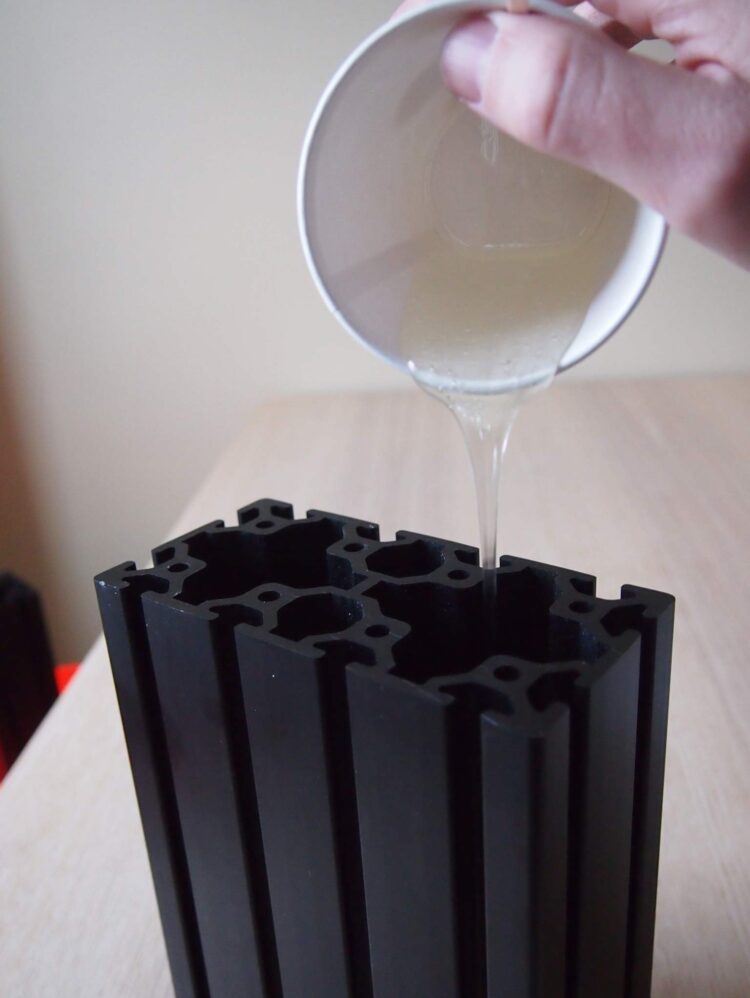

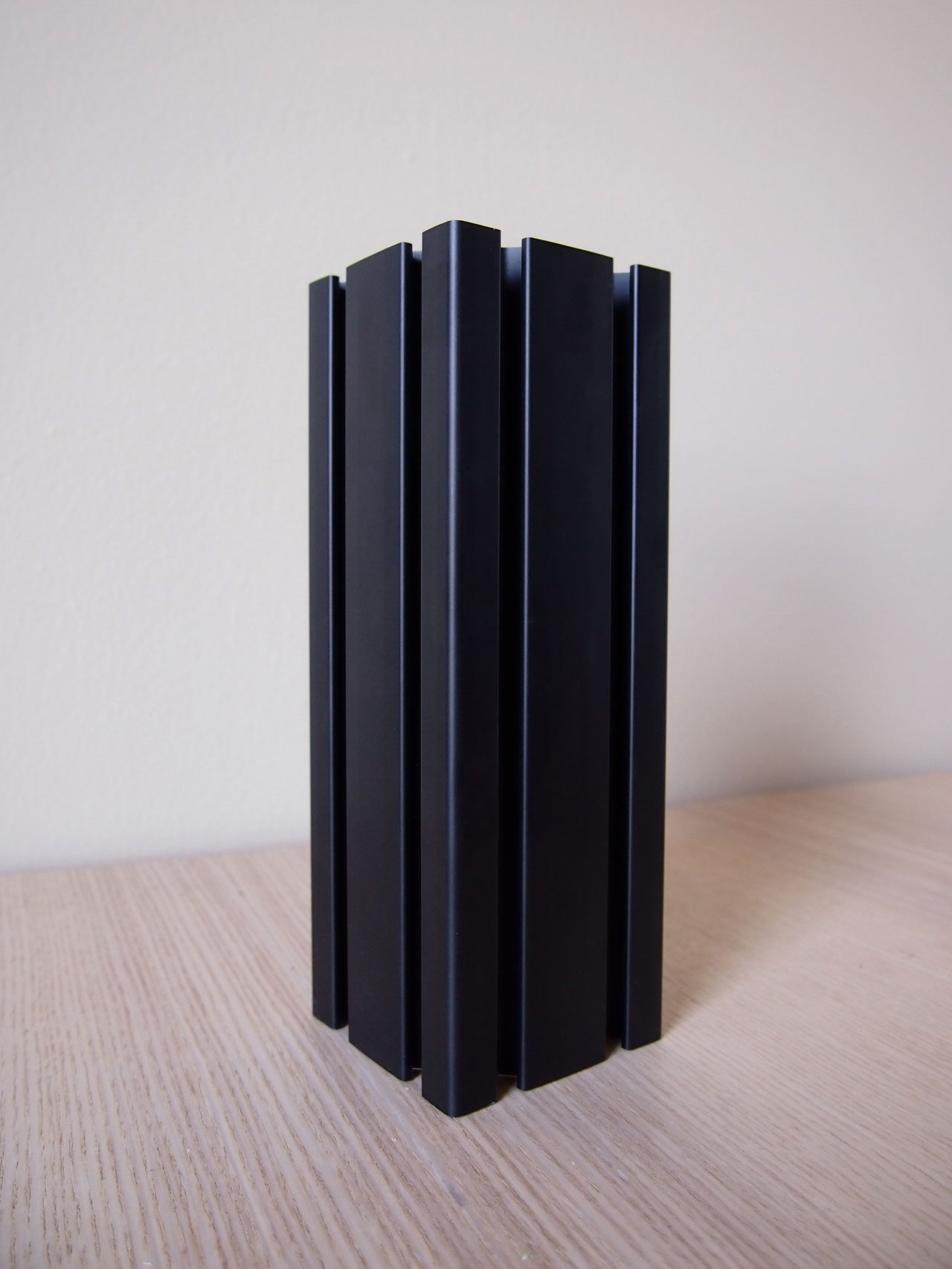

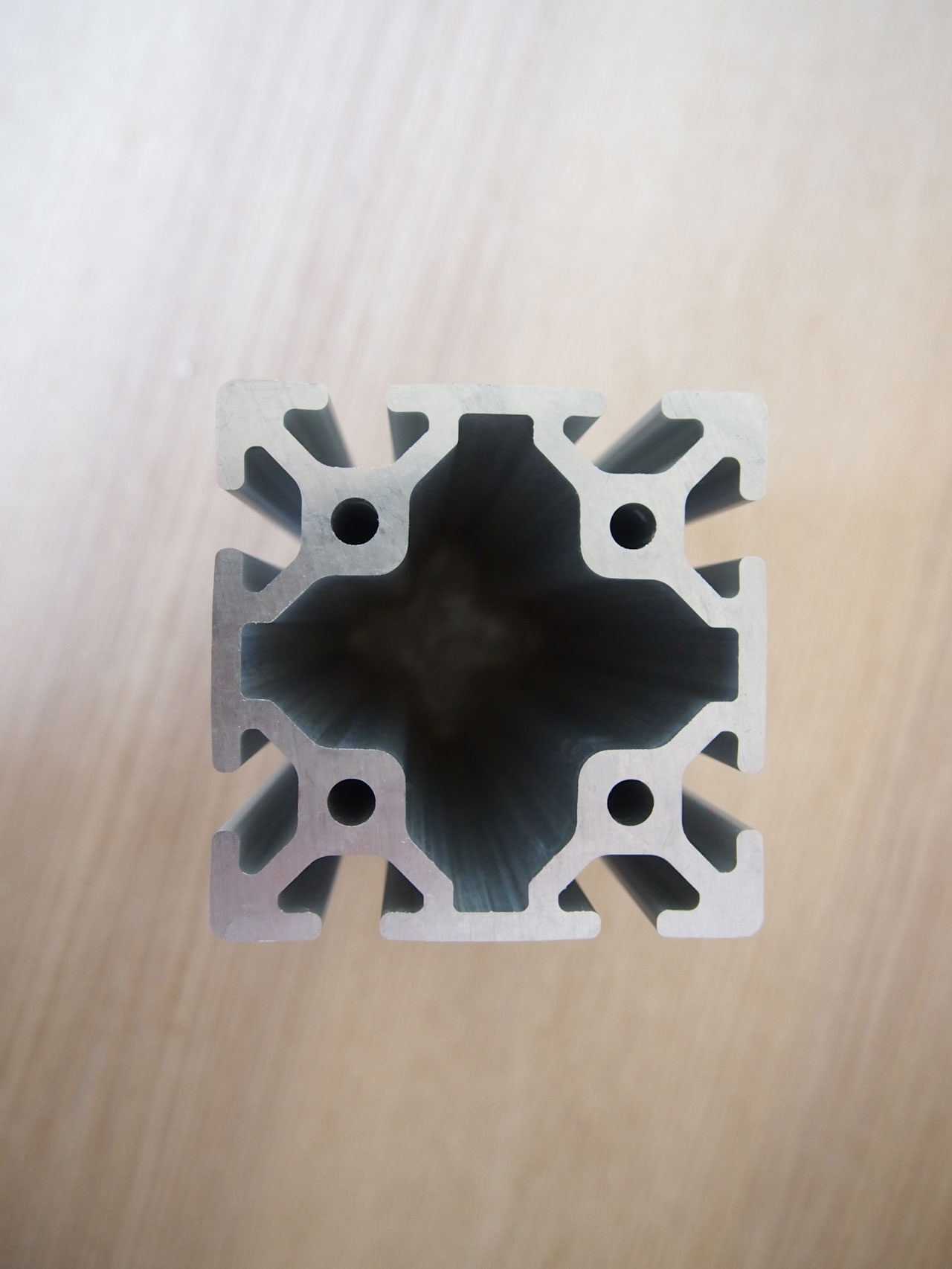

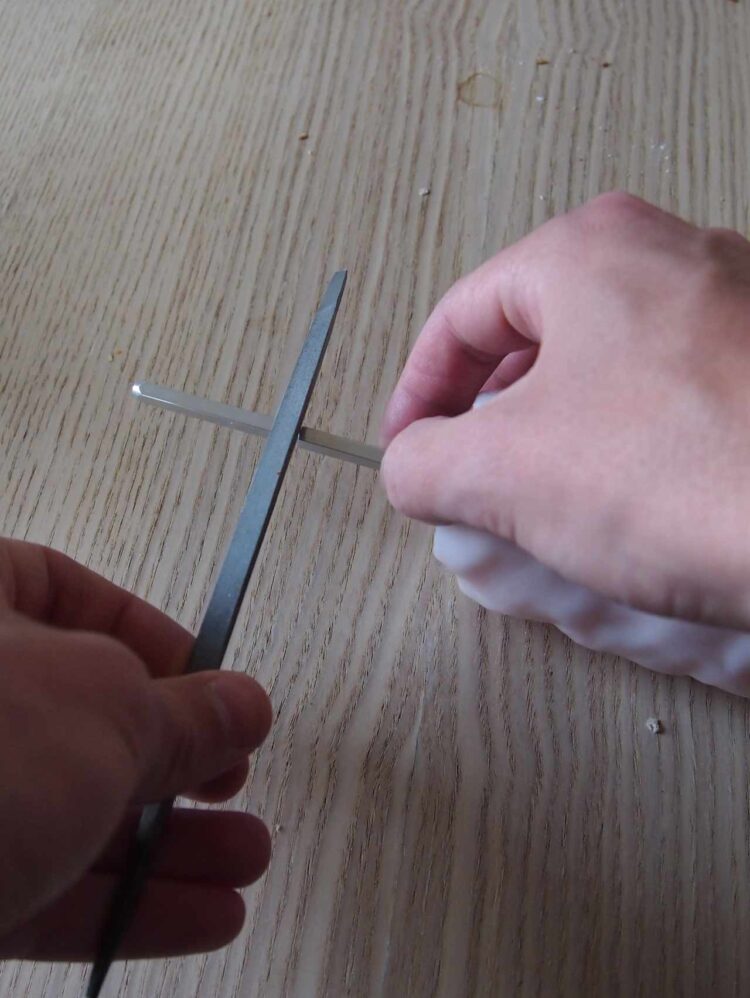

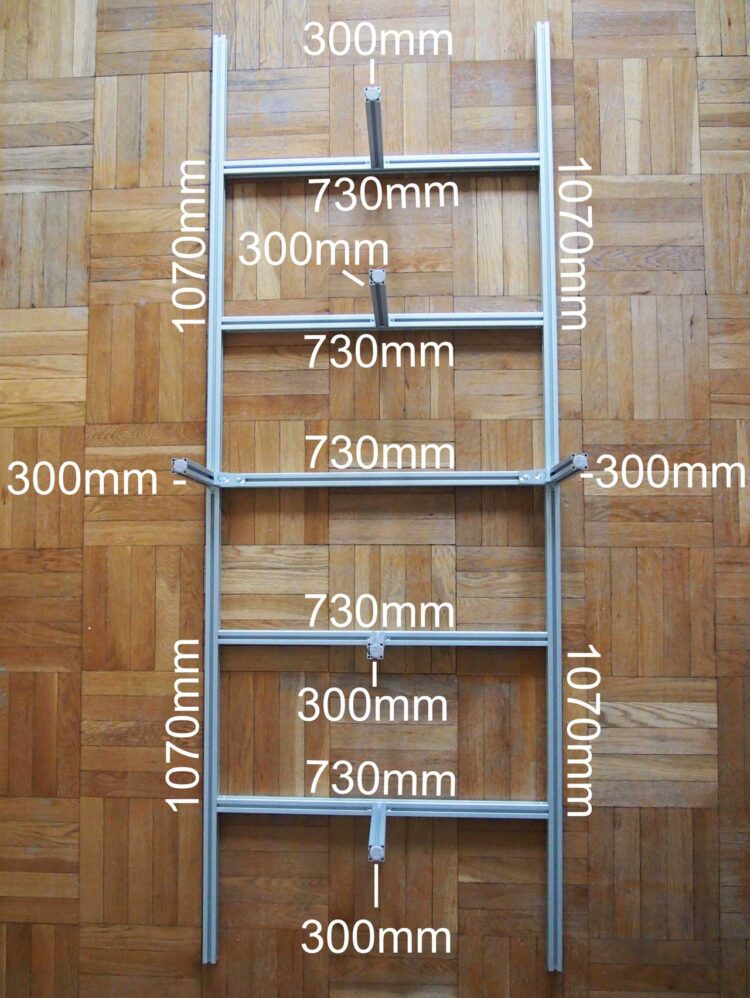

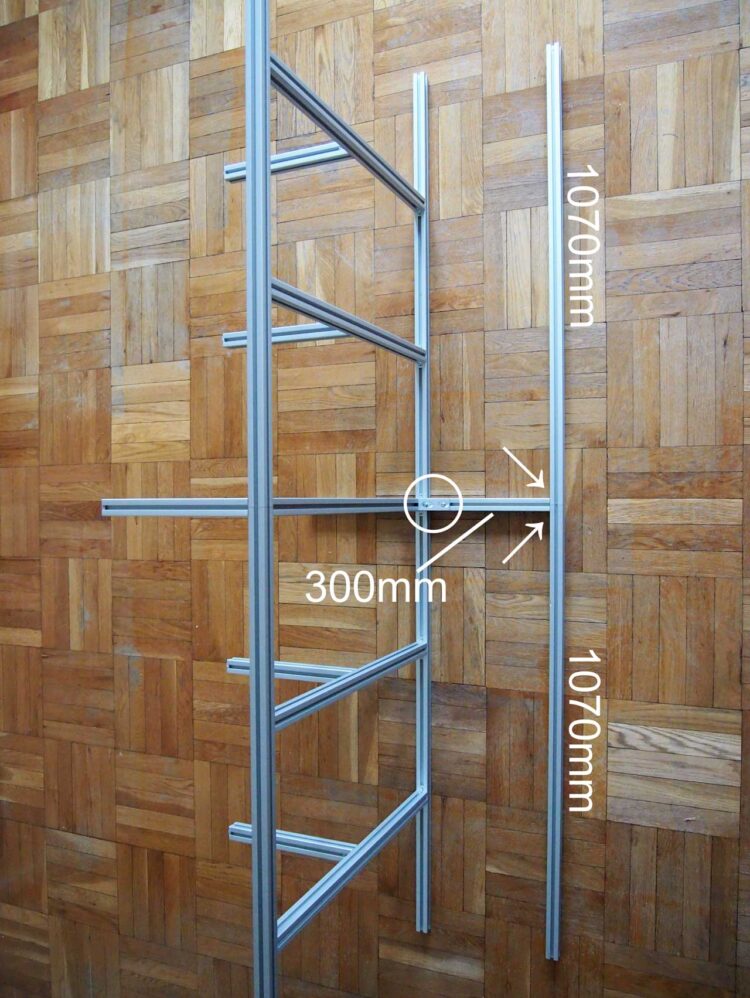

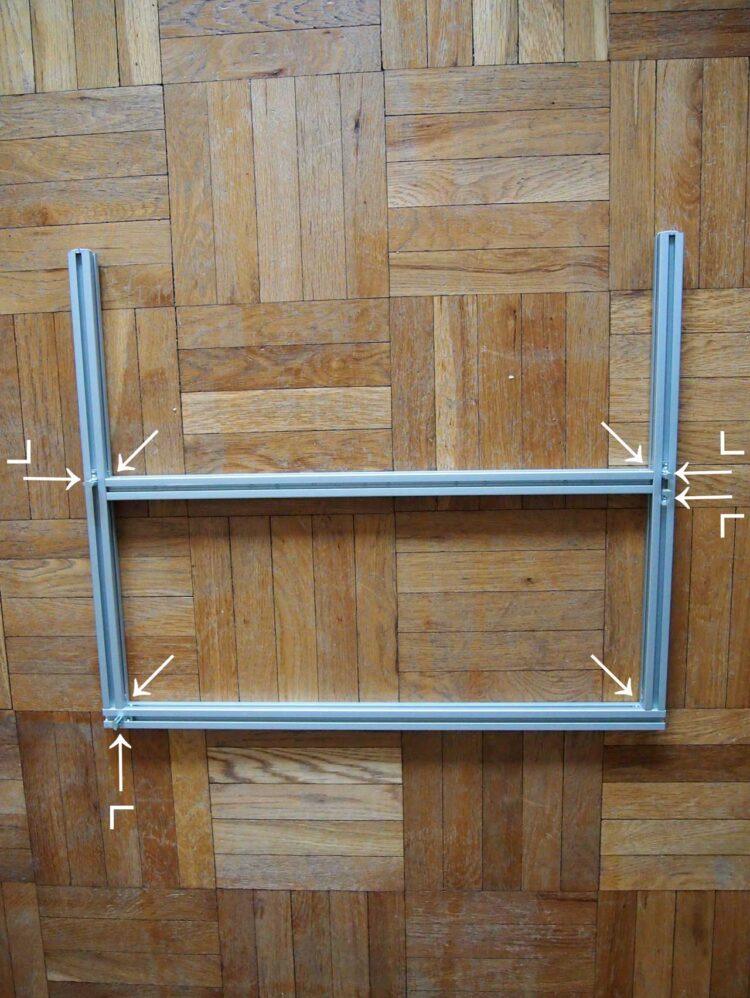

Designed alongside the One Gallon Floor Lamp and using similar utility-oriented parts, this pendant light replaces the standard pull chain switch and exaggerates the simple task of turning on a light. The full assembly process takes about 2 hours to complete. Steps include drilling a hole in the acrylic ball shade, wiring the lamp, and installing the moving strap switch. The parts cost a little over 100 USD on average.

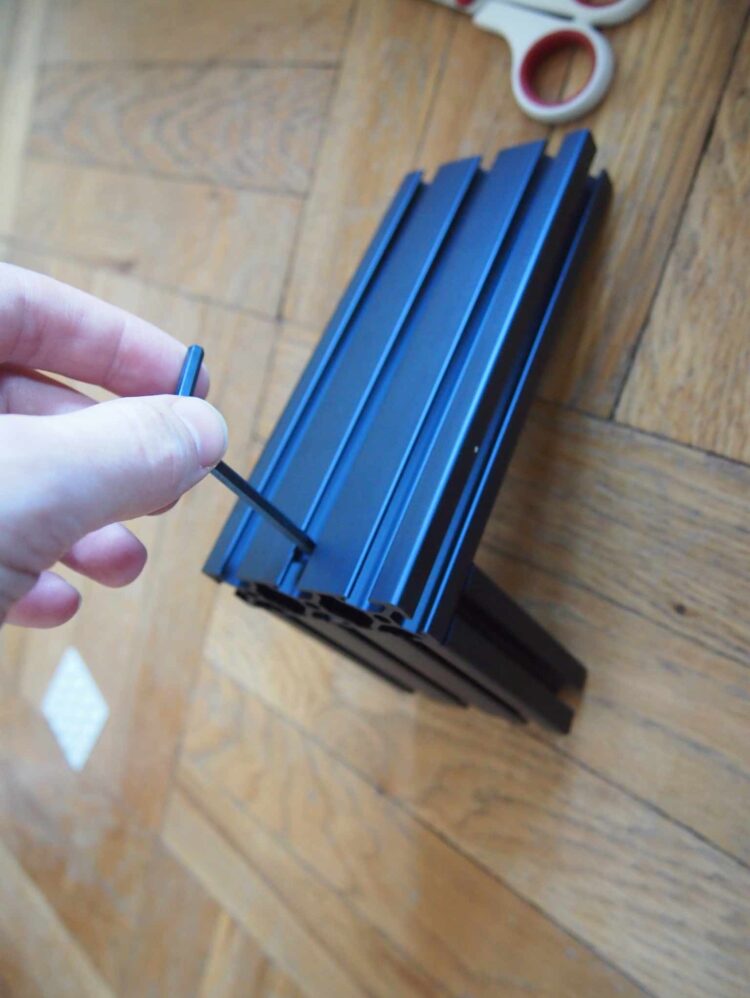

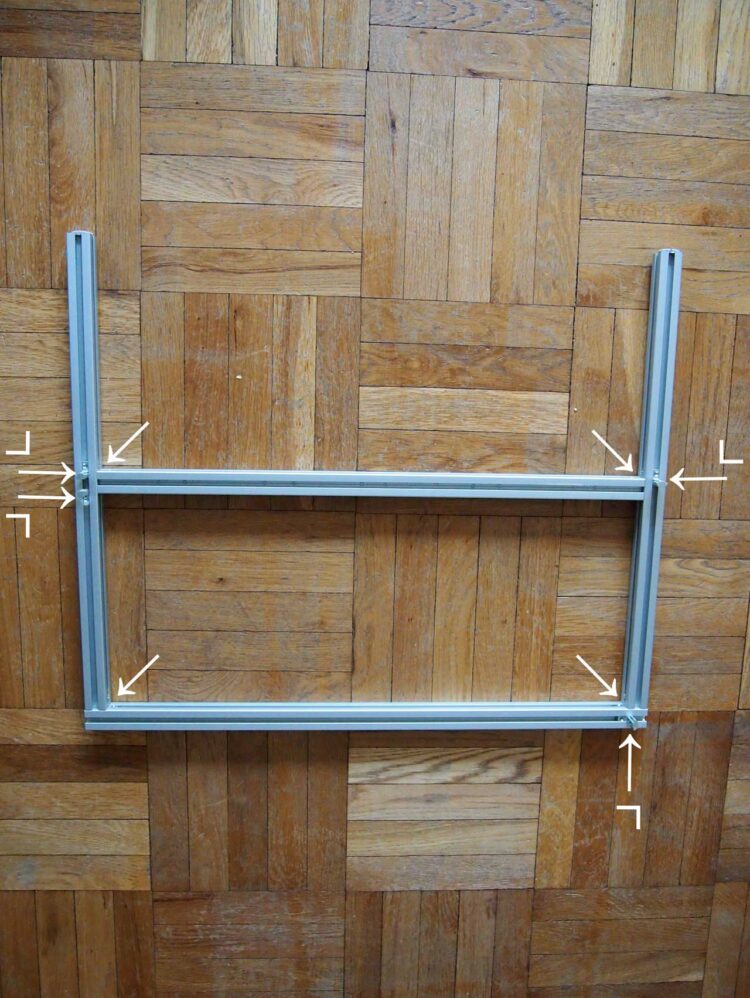

Assembly

Index

Parts

Polished Nickel Plated Neckless Ball Holder w/ Insert for 4in (10.5cm) Hole

Quantity required: 1

Straight Female Threaded Coupling, Nickel Plated, 1/2in W X 9/16in H, 1/8IPS

Quantity required: 1

Tools

Power Drill

Hole Saw, 1.5in (4cm)

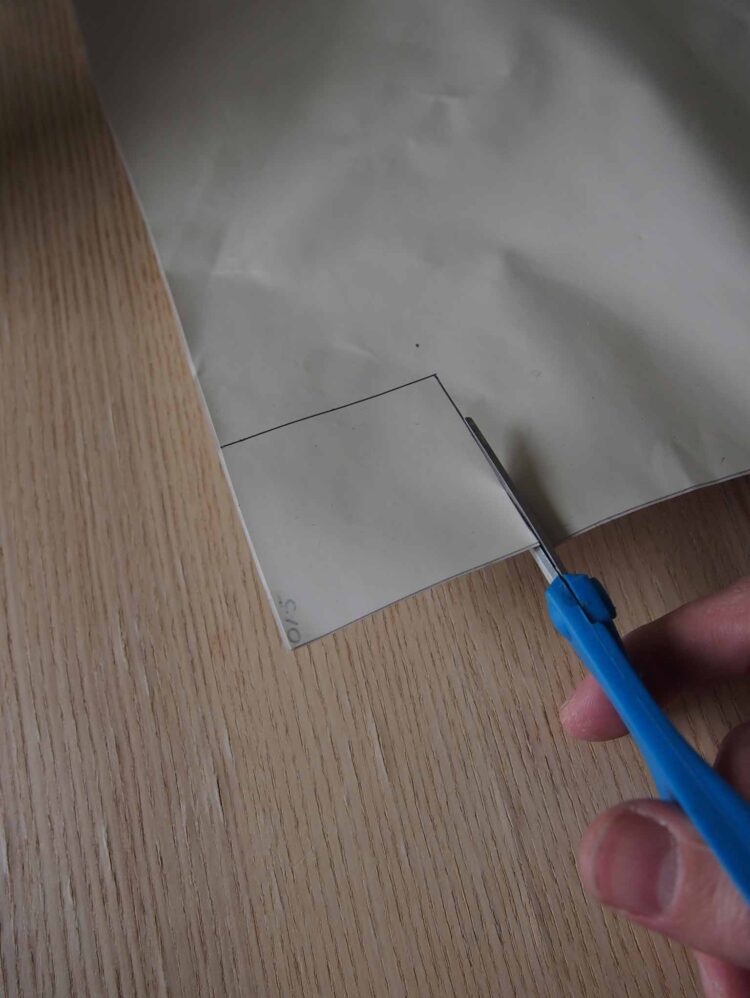

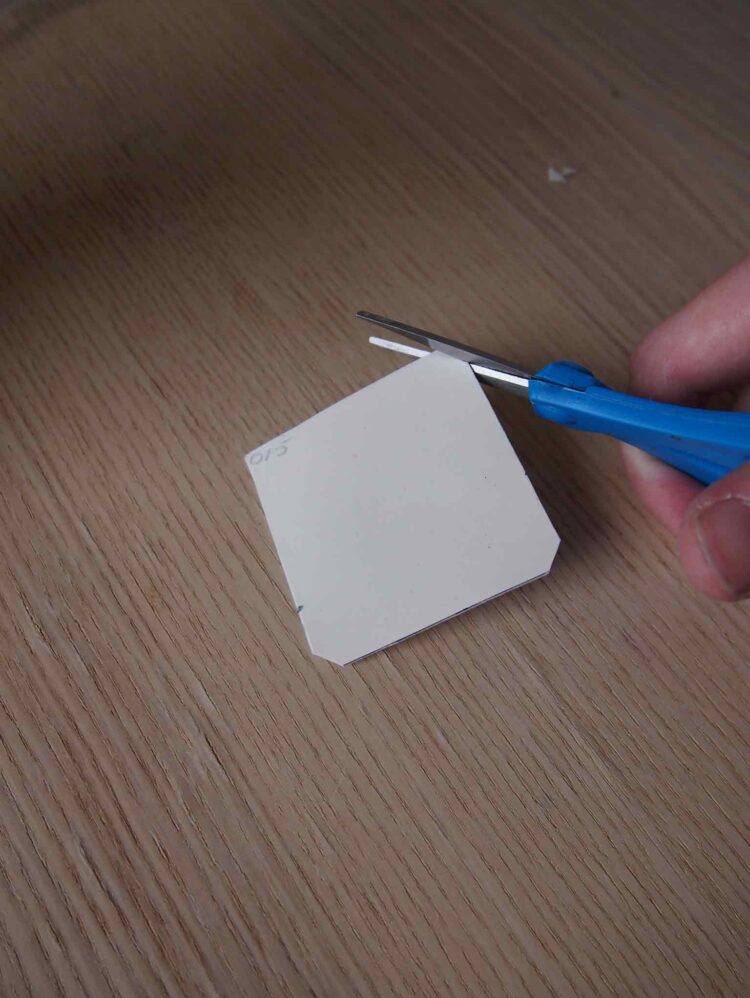

Utility Knife

Screwdriver, Flat Head

Help Each Other