Hempcrete Stool

Design and photography by Ian Anderson

Published in Fall 2019

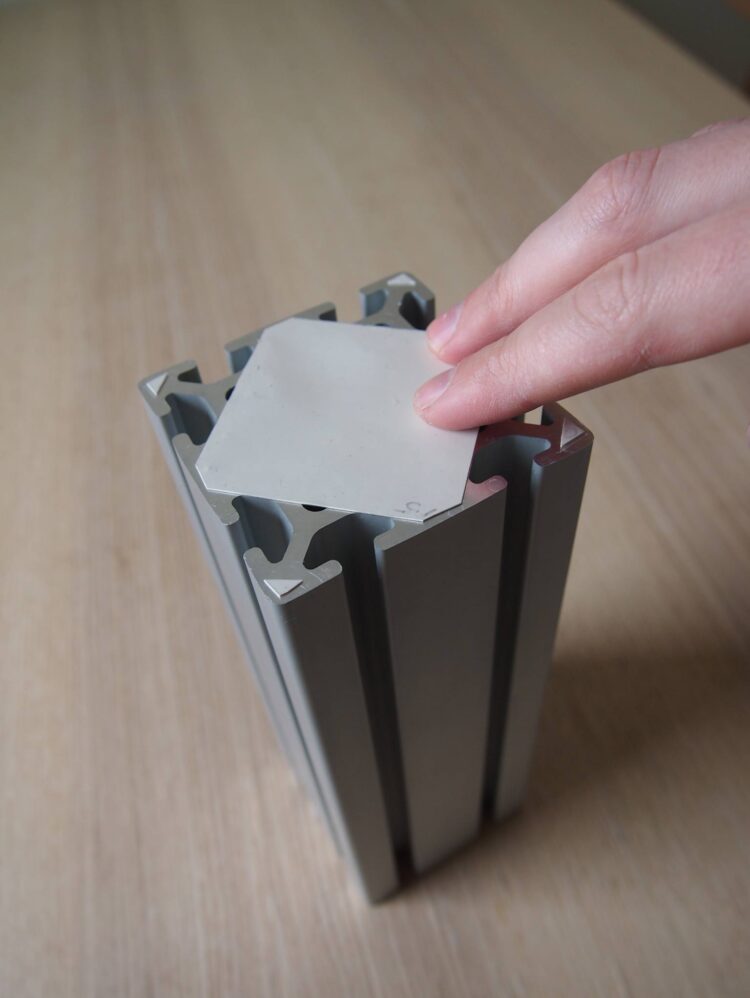

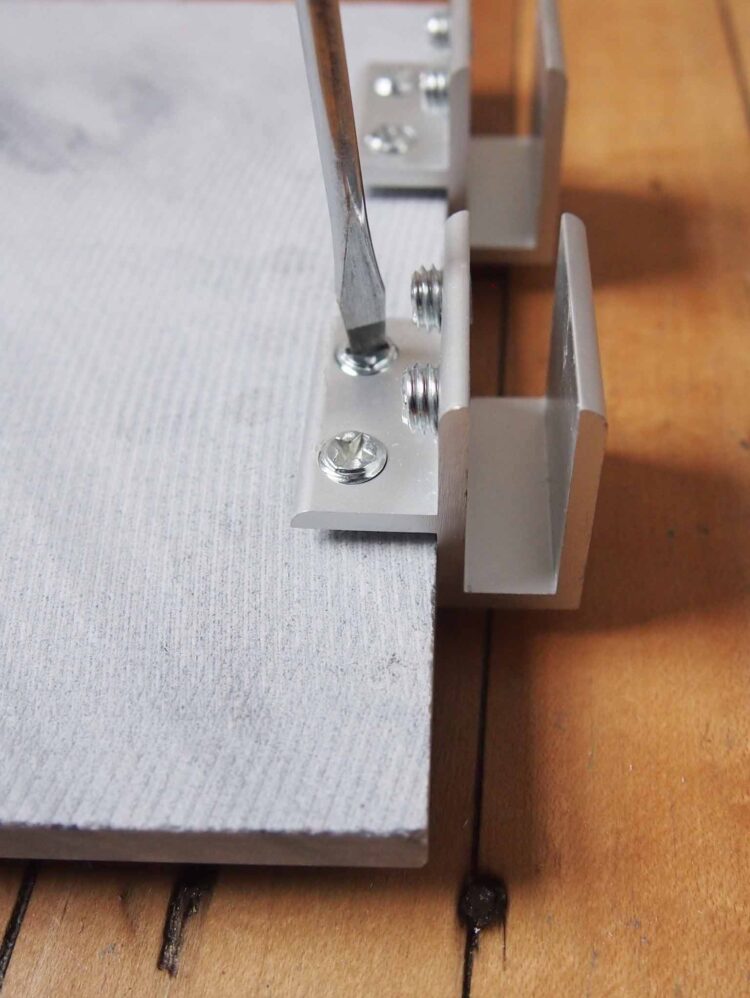

In making this stool, you will be producing an unconventional yet efficient building material with both insulation and thermal mass properties. Made up of hemp hurd, lime, and a binder material, hempcrete (as a single material) is a natural and carbon negative alternative to the abundant layers of insulation, drywall, cladding, etc… that cover the walls of our homes today. In some ways, the simple instructions for this stool are the same as instructions for building a wall of your home with this material. More on hempcrete here. The simple assembly process takes up to 1 hour to complete.

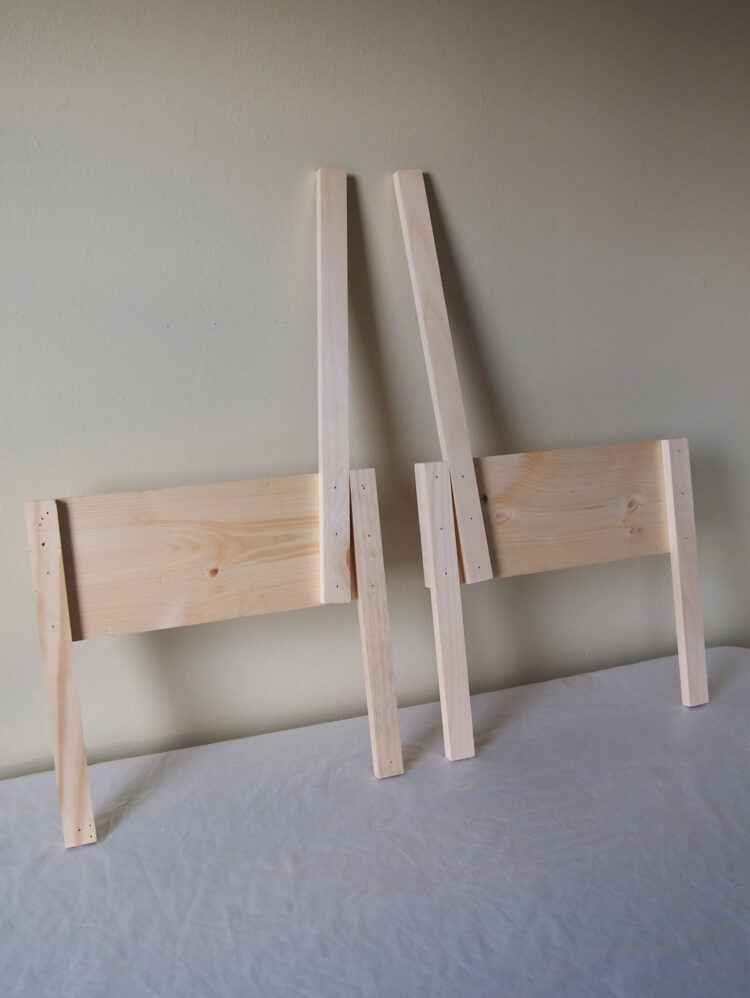

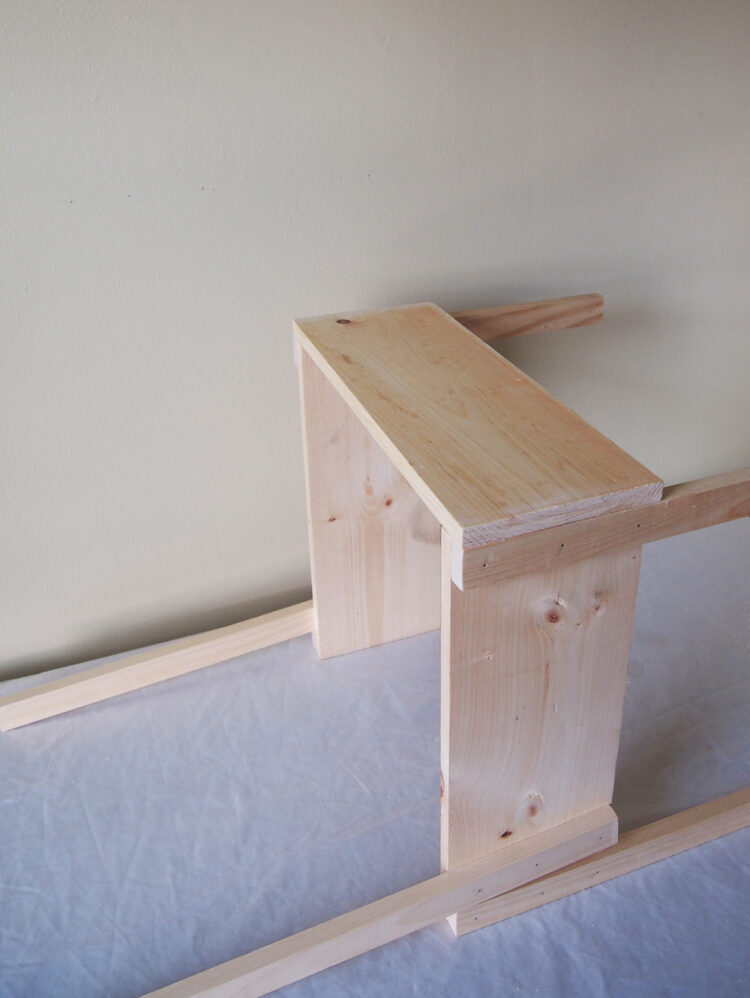

Assembly

Index

Parts

Hydrated Lime

Quantity required: 20lb (9kg)

Portland Cement

Quantity required: 5lb (2.3kg)

All Purpose Flour

Quantity required: A small hand full

Tools

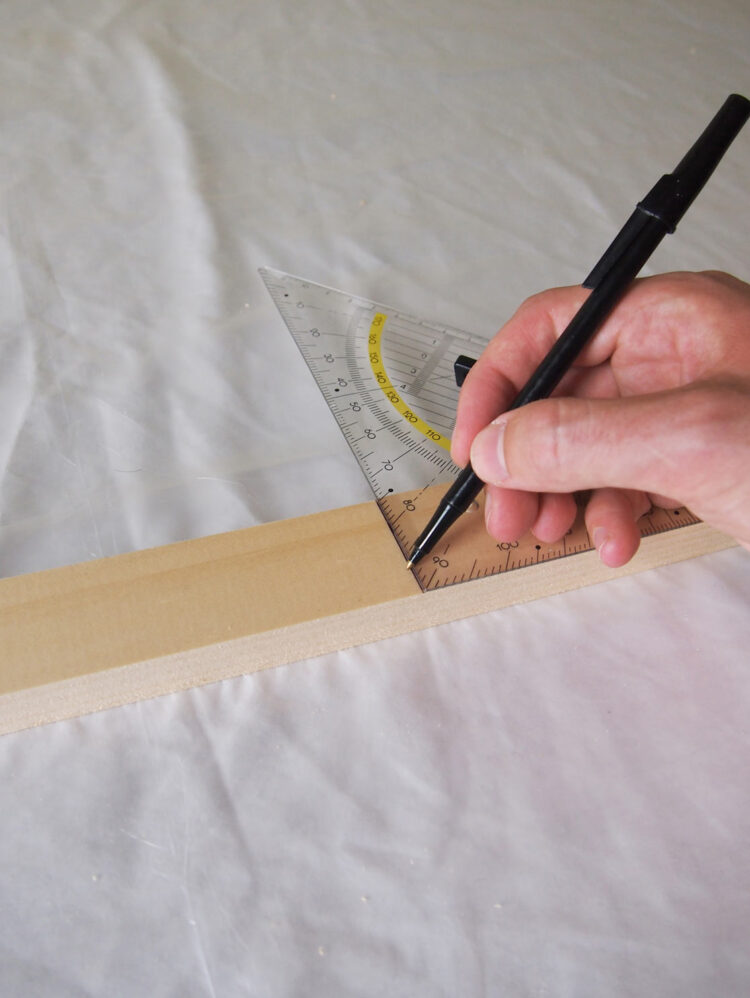

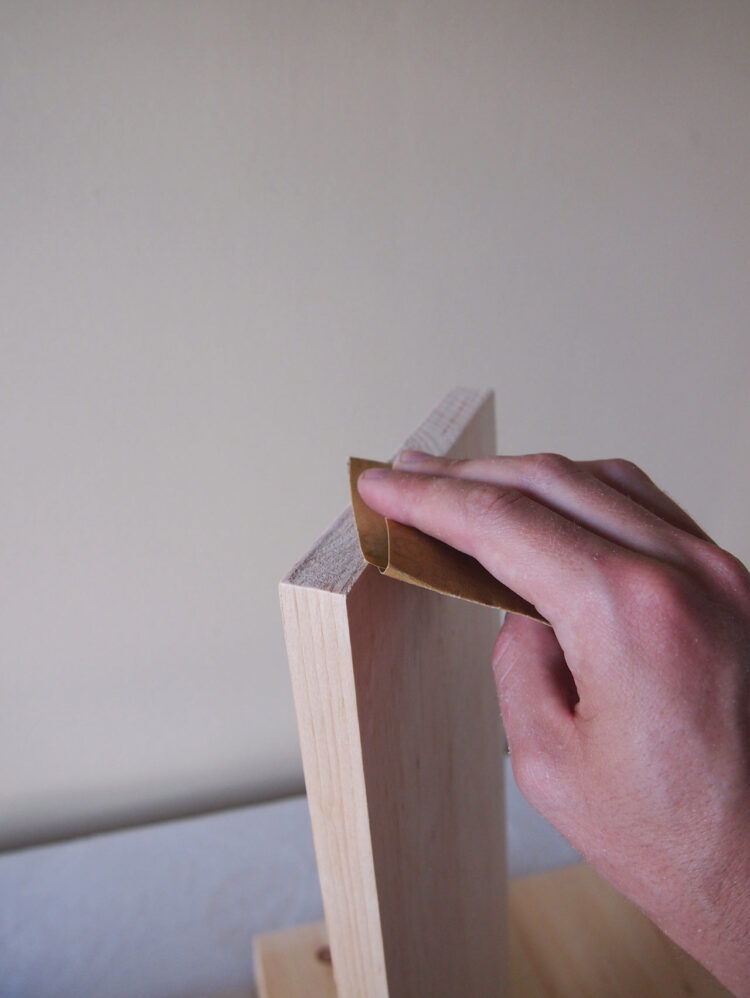

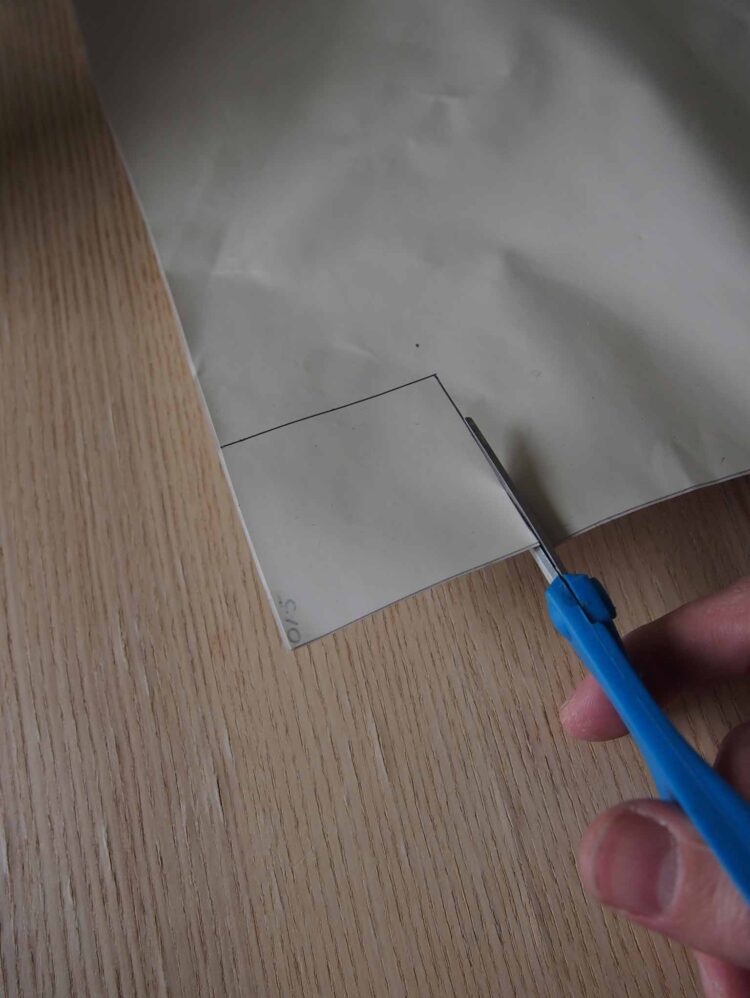

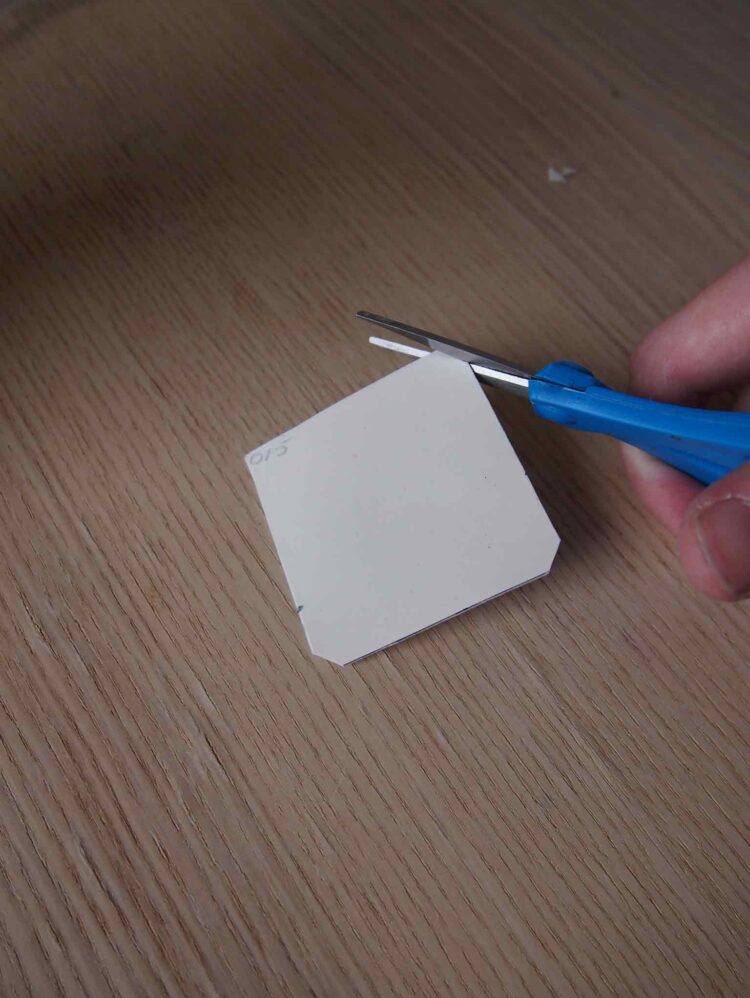

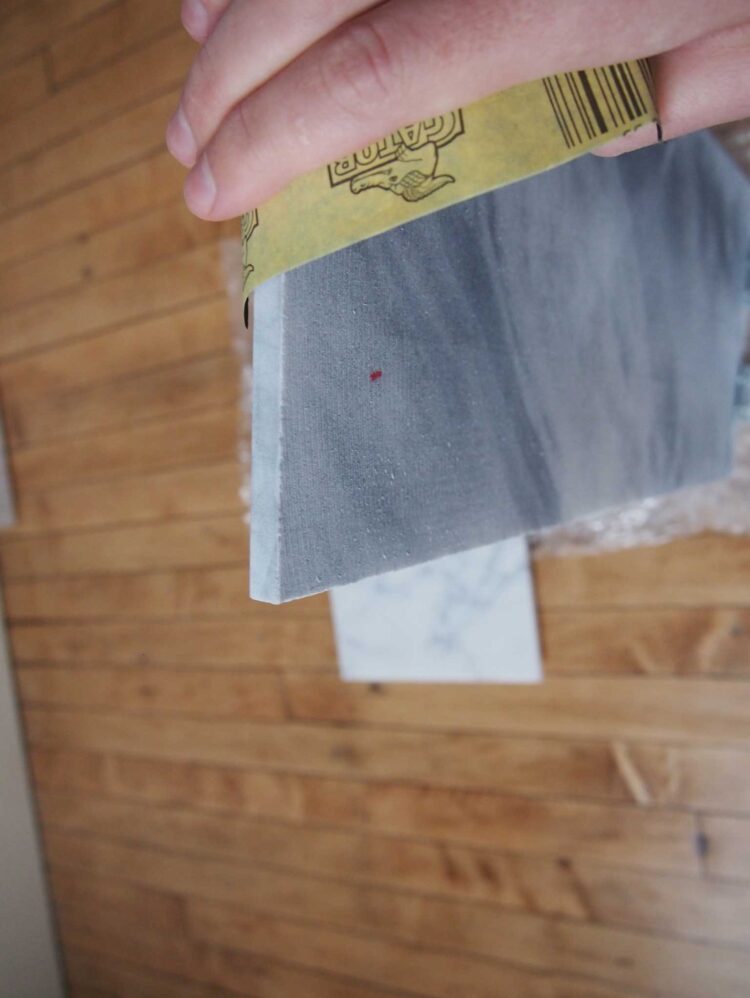

Cardboard

Packaging Tape

Mixing Bucket

Protective Plastic or Rubber Gloves

Disposable Cup

Alternative Parts

Metakaolin

*This material is much harder to obtain, but it is a by-product of some glass production, so less ecologically destructive to use than portland cement.

Replaces: Portland Cement

Quantity required: 10lb (4.5kg)

Help Each Other